Improved Flux-Cored Welding for Heavy-Duty Field Use

Understanding operator challenges is what drives innovation in the welding industry. For some, that challenge is outdoor welding, where using shielding gas is not optimal. In these extreme conditions, traditional MIG welding won’t necessarily work. Turning to a different process, such as self-shielded flux-cored welding (FCAW-S), allows for more effective welding in the field. When welding in harsh environments, operators require durable, rugged equipment that can withstand the elements and the nature of the work.

Operators utilizing self-shielded flux-cored welding demand a high level of flexibility and reliability in their equipment, which is why Bernard optimized the IronPro™ self-shielded FCAW gun to be extremely durable when welding in heavy-duty field operations.

Features that enhance flux-cored welding for heavy-duty applications

Operators need a gun that stays cooler in the hand and is lightweight, portable and reliable — handling the rigor of the toughest worksites while improving operator comfort. To improve usability and the overall user experience, IronPro introduces several enhancements to meet those needs and help overcome technical and operational challenges when out in the field.

Specifically, the IronPro 350 has a 350-amp rated output with a 60% duty cycle, making it ideal for operators working in construction, shipbuilding and heavy manufacturing. The design was further updated to include:

- Interchangeable neck options: The IronPro 350 features two rotatable neck options — one that’s 7 inches with a 60-degree bend radius and one that’s 12 inches with a 45-degree bend radius. These allow operators to ergonomically access even the most challenging, out-of-position welds. The neck can be rotated for a trigger-on-top approach, allowing for even more dexterity and customization at the joint.

- Sealed trigger: The trigger is designed to keep the area slag- and spatter-free, reducing maintenance downtime. Being non-metallic, it absorbs less heat, and it’s made with a sealed switch that helps keep out dust and dirt, leading to a longer lifespan.

- Lighter cable: The weight and bulk of higher amperage gun cables can lead to fatigue over extended periods of time. The cable for the 350 is lighter, making it more mobile and user-friendly for a welder on a day-to-day basis.

Incorporating all the updated design features mentioned above, IronPro 450 is also available for higher amperage applications, supporting up to 3/32″ wire size. IronPro 450 has a 450-amp-rated output with a 60% duty cycle.

Additional ways to improve field performance

To keep operators welding in tight positions longer, using AccuLock™ S consumables will increase contact tip life, resulting in fewer tip changes and increased overall performance with fewer points of failure. To further improve field performance, the cable liner incorporates Bernard® E-Z Feed™ technology, ensuring a reliable and smooth feed, minimizing chatter and poor arc characteristics. The superior feeding performance, paired with high-quality consumables, leads to more consistent welds, minimizing rework.

The tip insulator was redesigned to be more durable, withstanding more aggressive weld parameters to keep the electricity from short-circuiting between the tip and neck. Additionally, the insulator transitioned from being a slip-on to a thread-on, allowing it to stay in place better. These design improvements help minimize bridging from spatter and improve operator safety by ensuring the contact tip remains isolated to allow current to flow correctly through the wire to the weld puddle. Operators can choose between composite tip insulators, for increased joint access, or armored tip insulators, which are well-suited for higher amperage applications. These options allow operators to better customize their IronPro to suit the needs of their applications.

When welding heavy-duty applications in the field, operators need power, durability and consistency. The IronPro 350 offers improvements that exceed those demands. Welders can elevate their welding performance — and experience the productivity and quality benefits self-shielded flux-cored welding offers.

4 Reasons Genuine Consumables Lead to Better MIG Welds

4 Reasons Genuine Consumables Lead to Better MIG Welds

Welders must be able to rely on every aspect of their equipment, and consumables are an integral component of a high-quality weld. When you notice an uptick in downtime and consumables consumption, it’s time to take a deeper look at what the culprit could be. An easy place to start is by looking at the quality of the consumables you’re using. Lower-quality consumables can lead to major expenses in the long run — as seen in lost production, weld rework and the cost of constant replacements.

Original equipment manufacturer (OEM) consumables are the right choice for improved operations and consistent, high-quality welds. Below are four reasons you should consider investing in genuine consumables over lower-quality options.

- Consumable quality affects your performance

Even the best MIG guns or the most highly trained operators cannot offset the impact of poorly made consumables on performance. OEM consumables are manufactured using high-quality materials, which helps deliver the arc stability needed to create smooth, even welds with minimal defects. In addition to helping improve weld integrity and facilitating more durable weld joints, genuine consumables also help prevent excessive spatter and minimize post-weld cleanup.

Because OEM consumables are manufactured for reliability, they have consistent diameters and surface conditions that ensure smoother feeding through the gun. By contrast, non-genuine consumables are often made from low-quality materials and may not consistently meet key manufacturing specifications.

2. OEM consumables are expertly designed to be reliable

Genuine consumables are backed by research, technology and expertise, having been produced to ensure the material composition and mechanical properties are consistent and reliable. Keeping those details at the forefront makes for stable arcs, high-quality welds, fewer points of failure and simplified maintenance. Their ease of use can even help to reduce welder training times and shorten your troubleshooting list if problems do arise.

Copycat manufacturers are also less likely to submit their consumables to the rigorous testing and quality assurance processes that OEMs follow.

AccuLock ™ consumables have been designed to flawlessly integrate into Bernard® semi-automatic and Tregaskiss® fixed automatic and robotic MIG welding guns and to address welders’ most common pain points.

For semi-automatic MIG welding applications, the AccuLock™ S consumables system paired with front load E-Z Feed™ liners reduces liner trim length errors and erratic wire feeding while simultaneously increasing contact tip life. The front load liners are locked and concentrically aligned to both the contact tip and power pin. This eliminates misalignment and provides a flawless wire feed path, ensuring uninterrupted delivery of the wire to the weld puddle. As a result, operators have fewer burnbacks, bird nests and erratic arcs.

The AccuLock R consumables system is available for robotic or fixed automatic MIG welding applications. With these consumables, operators have the opportunity to realize significant improvements, like increasing contact tip life span and decreasing issues with contact tip cross-threading.

For operations constantly managing complex or costly consumables inventories, AccuLock S and AccuLock R consumables systems share a common contact tip — making for simplified part inventory across mixed fleets of semi-automatic and automated welding applications. Operations who are looking to get more life out of their consumables but aren’t using Bernard or Tregaskiss guns can purchase the conversion series consumables to still experience the benefits of a high-quality system.

3. Using low-quality products limits your manufacturer’s ability to help

A good OEM is invested not only in the performance of its products but also in the overall user experience, which extends to customer service. Reputable OEMs usually have expert technical support teams that help with troubleshooting and provide solutions if something goes wrong. They can also share product tips and offer advice, like how to make your MIG gun consumables last longer.

However, if you’re using nongenuine consumables and parts, technical support teams are unable to offer such assistance. Often, if an issue arises involving lower-quality parts, it will be essential to order genuine parts and wait for them to arrive to see if the issue still occurs before the OEM team can offer support. Using genuine parts from the get-go means you can get expert advice right away — or avoid issues altogether.

4. OEM products can have a longer life

Because OEMs are making greater investments in materials, design and testing, that means OEM consumables usually cost more than low-quality consumables. But, as the saying goes, you get what you pay for. Consumables are probably not your biggest cost — labor is. So any money you save by using cheaply made consumables could be offset by the extra labor required to frequently change tips, troubleshoot equipment failure or rework a faulty weld. Those looking for superior performance and longevity find that OEM options can equate to more arc-on time — and more products out the door.

AccuLock contact tips are designed so that 60% of the tip is buried within the diffuser for less exposure to the heat of the arc and more cooling from shielding gas. This gives the tip a life that can be two to three times longer than other tips.

All told, because genuine consumables are designed specifically for your MIG welding gun, they can last longer, be more reliable and deliver higher-quality welds — ultimately enhancing the operator experience and your welding operation’s bottom line.

Introducing The Bernard® Clean Air E™

Introducing The Bernard® Clean Air E™

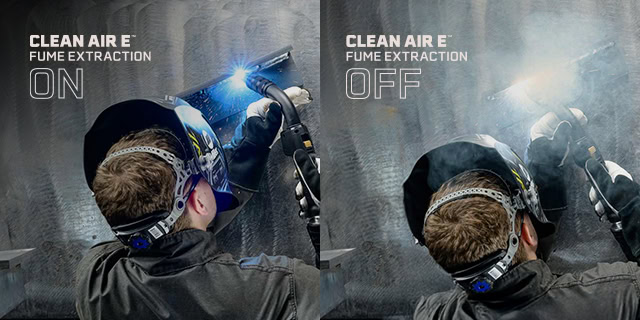

Welding professionals face daily challenges in keeping their work environment clean and safe. With strict weld fume regulations, effective fume control is more important than ever. The Bernard® Clean Air E™ fume extraction MIG gun helps by capturing welding fumes directly at the source without sacrificing performance.

Why Source Capture Matters

Capturing weld fume as close to the point of generation as possible, also known as source capture, is one of the most effective ways to reduce exposure. Unlike general ventilation or ambient air systems that dilute fumes, source capture methods like fume extraction guns immediately remove hazardous particles, helping improve air quality for operators and surrounding workers.

The Clean Air E™ captures up to 95% of fume at the source. The gun is built with adjustable extraction control through interchangeable shroud lengths and a slider allowing operators to fine-tune suction levels without affecting shielding gas coverage. This balance is critical for maintaining weld quality while maximizing fume capture.

Key Benefits of the Clean Air E™

Efficient Extraction

By removing up to 95% of fumes directly at the arc, the Clean Air E™ helps reduce exposure risks and contributes to a cleaner workspace.

Enhanced Ergonomics

With a lightweight handle design, the Clean Air E™ allows you to weld longer without fatigue. The ball swivel at the rear of the handle makes maneuvering easier, even in difficult positions.

Engineered for Endurance

This fume gun is built to withstand the toughest working environments. Made from durable, tested materials, it features a robust and straightforward design for easy maintenance.

Designed for Demanding Applications

Ideal for high-amperage and high-deposition rate applications, the Clean Air E™ is well-suited for industries such as: Shipbuilding, Heavy equipment manufacturing, General fabrication and manufacturing

Ergonomic and Easy to Use

Unlike bulky ventilation systems, fume extraction guns like the Clean Air E™ seamlessly integrate into a welder’s workflow. With a lightweight, ergonomic design and a user-friendly adjustment slider on the guns handle, it operates much like a standard MIG gun while providing the added benefit of fume extraction.

Customizable

We know every welder has their own preference when it comes to welding style. That’s why we designed two trigger options—a button and a lever, plus an extended lever for added comfort. We also made the shrouds interchangeable, offering three lengths to optimize either weld visibility or fume extraction, depending on your application.

A Smarter Step Toward Safer Welding

No single solution eliminates all welding fume exposure, but using a fume extraction gun alongside a compatible extraction unit like the Miller® Filtair®215 can significantly improve a workplace environment. The Bernard® Clean Air E™ provides a practical, effective way to prioritize welder safety and performance.

It starts at the source™

For Immediate Release BEECHER, Ill./WINDSOR, Ontario (March 20, 2025) — Bernard announced the release of the new Clean Air E™ fume extraction MIG gun, the newest high-efficiency fume extraction gun in the brand’s lineup. Crafted for efficient extraction, enhanced ergonomics and engineered endurance, this gun sets a new standard in MIG welding fume capture technology. With an ongoing priority to ensure safer, cleaner work environments for operators coupled with heightened fume standards being implemented across the country, Bernard saw an opportunity to evolve the standard fume extraction gun to maximize its efficiency and usability. Bernard took customer and welder feedback and designed a product that would be the most impactful for welders in a next-generation fume extraction gun. The team applied that feedback throughout the research and development process until it resulted in the Clean Air E™, which offers solutions to common operator pain points, including: · Efficient extraction: The Clean Air E™ achieves up to 95% fume capture right at the source, which improves air quality in the workspace and reduces OSHA-related risks. · Enhanced ergonomics: The ergonomic design reduces strain and fatigue on welders, which allows them to focus on precision and quality for extended use. · Engineered for endurance: The Clean Air E™ features durable components and long-life consumables, which reduces downtime and maintenance costs, delivering a lower cost of total ownership. “When it comes to welding, operators seek the trifecta in their gun: ergonomics, extraction performance and ease of maintenance,” said Jerome Parker, product manager, Bernard. “The Clean Air E™ was designed alongside actual users to ensure we arrived at a solution that redefined traditional fume capture guns for the modern welder, enhancing both their operator experience and their weld environment.” On the gun itself, the Clean Air E™ offers enhanced features for easier and more efficient use: · Improved weld access: Three nozzle shroud lengths allow operators to balance fume capture with weld access and improved visibility of the weldment. · Instant flow adjustment: The new flow control slide on the back of the handle enables welders to easily reduce airflow by up to 10 cfm to help overcome porosity issues. · Upgraded handle comfort: Two handle styles are available to suit different grip styles and hand sizes, with internals contoured to enhance airflow and fume capture. The lever trigger can also be mounted on top for additional comfort. · Increased flexibility: A durable, lightweight aluminum ball swivel at the end of the handle provides 15 degrees of extra flex in any direction for additional improved ergonomics. · Maximized airflow: A new Y-connector offers contoured internals that maximize airflow, with a vacuum outlet that is compatible with any fume extraction unit. For a premium fume extraction pairing, operators have the option to connect the Clean Air E™ to the Miller® FILTAIR® 215. Learn more about how the Clean Air E™ can deliver safety, performance and comfort for welders at https://www.startsatthesource.com/ About Bernard Bernard, a leading manufacturer of premium semi-automatic MIG welding guns and consumables, is dedicated to enhancing welding productivity and performance. Headquartered in Beecher, Illinois, Bernard is known for innovative solutions that prioritize operator comfort, ease of maintenance, and exceptional durability. Bernard is a proud brand of Illinois Tool Works Inc. (NYSE: ITW). For more information, visit BernardTregaskiss.com, call 1-855-MIGWELD (1-855-644-9353), email CS@itwmig.com. Contact: Lauren Smith, Hiebing for Bernard/Tregaskiss phone: +1 6082684408 lsmith@hiebing.com Keep your Bernard® Clean Air E™ Fume Extraction MIG Gun performing at its best by replacing the Y-connector when needed. This quick guide walks you through the simple steps to ensure a secure fit and maintain optimal fume extraction efficiency. Watch now to keep your system running smoothly and your workspace cleaner. Instructions Separate connector halves. Push rear hose swivel forward to slide it out of the cavity. Slide the hose assembly forward and remove the remaining Y Connector half. Place the new rubber boot into the new Y Connector set. Position the cable assembly in the Y Connector channel, ensuring proper alignment with rubber boot. Pull the hose assembly back into the swivel cavity and ensure it is taut (no slack). Confirm the hose and cable assemblies are properly seated and secure. Align the Y Connector halves and reinstall screws. Find more resources at www.startsatthesource.com Properly connecting your Bernard® Clean Air E™ Fume Extraction MIG Gun to a fume extraction unit is key to maximizing performance and maintaining a cleaner work environment. In this video, we walk you through the simple steps to ensure a secure and efficient connection, helping you get the most out of your fume extraction system. Instructions Thread hose onto the fume port of the fume extraction unit and tighten securely. Attach the opposite end of hose to the 1-3/4” port on the Y Connector, ensuring all connections are tight. Find more resources at www.startsatthesource.com Maintaining your Bernard® Clean Air E™ Fume Extraction MIG Gun is quick and easy! Watch as we walk through the simple process of replacing the neck and trigger, ensuring your gun stays in top working condition. Designed for durability and performance, the Clean Air E™ makes maintenance hassle-free so you can focus on the job. Instructions Changing the Inner Neck Assembly Remove the Shroud and Consumables: Unthread the knurled smoke shroud from the smoke tube assembly and remove the front end consumables. Separate the Handle Halves: Remove the socket head cap screws (7/64″ hex) and keep them for later. Remove the Smoke Tube Assembly: Slide it forward and off the inner neck assembly. Loosen the Lock Nut: Place the neck in a vise (don’t over-tighten). Use 3/4” wrenches to loosen the lock nut on the neck. Unthread the Neck: Once the lock nut is loose, unthread the neck from the end fitting by hand. Replace the Neck: Add the lock nut to the new neck, thread it into the cable end fitting, and tighten by hand. Secure the neck in a vise and torque the lock nut/end fitting connection to 30 ft-lbs (40.7 Nm). Reassemble the Handle: Position the neck and smoke tube assembly into the handle. Ensure the trigger components and vacuum slide are correctly placed, with trigger wires routed properly. Secure the Handle Halves: Use the handle screws and torque them to 10 in-lbs (1.1 Nm). Changing the Switch – Button Model Separate the Handle Halves: Remove the screws completely. Remove the Terminals: Use needle nose pliers to remove the terminals from the trigger switch. Attach the New Trigger: Secure the terminals to the new trigger, position it in the right handle half, and ensure the wires are routed correctly. Reassemble the Handle: Reinstall the second handle half, tighten all screws, and torque to 10 in-lbs (1.1 Nm). Changing the Switch – Lever Model Separate the Handle Halves: Remove the screws completely. Remove the Switch Assembly: Use needle nose pliers to disconnect the terminals and carefully remove the lever. Attach the New Switch: Secure the terminals to the new switch assembly, install it into the mounting cavity, and reinstall the lever. Reassemble the Handle: Ensure all components are correctly positioned, then reinstall the second handle half, starting with the lever screw. Tighten all screws and torque to 10 in-lbs (1.1 Nm). Changing the Vacuum Slide Switch Separate the Handle Halves: Remove the screws completely. Remove the Slide Switch: Carefully take it out of the channel in the handle half. Install the New Slide Switch: Position it in the channel, ensuring it moves freely. Reassemble the Handle: Keep the slide switch properly aligned and reinstall the screws, tightening them evenly and torquing to 10 in-lbs (1.1 Nm) Find more resources at www.startsatthesource.com We designed the Bernard® Clean Air E™ Fume Extraction Gun with interchangeable shrouds, giving you the flexibility to optimize fume capture for your specific welding application. Choose from a longer shroud for maximum fume extraction, a medium shroud for the perfect balance of weld access and fume capture, or a short shroud for maximum weld access while still extracting fumes. Instructions Simply unthread the fume shroud from the neck tube and rethread your desired shroud based on your nozzle size and welding application. Find more resources at www.startsatthesource.com Need to replace the hose on your Clean Air E™ fume extraction gun? We’ve got you covered! Follow these simple steps to swap it out quickly and keep your fume extraction system performing at its best. Watch now and ensure clean, efficient welding every time. Instructions 1. If replacing the vacuum hose assembly, remove all screws to separate the handle halves and remove the front hose swivel from its cavity. 2. Remove screw covers and two screws securing the rear handle, then slide the rear handle and strain relief backward to remove them. 3. Remove screws on the Y Connector and open to expose the cable assembly and rear hose swivel. 4. Pull the vacuum hose assembly backward to remove it from the cable assembly. 5. Slide the new vacuum hose assembly forward over the cable assembly until the front hose swivel rests in its cavity. Align the handle halves and reinstall all screws to retain hose assembly within handle. 6. With the cable straight, pull the hose and position it into the Y Connector, ensuring no slack. Tighten Y Connector screws, correctly positioning rubber boot within the Y Connector. 7. Slide rear handle and strain relief forward onto the cable assembly and secure with screws and screw covers. Find more resources at www.startsatthesource.com Regardless of your experience level, keeping your weld environment safe is a top priority. A multifaceted approach to fume mitigation can help you maximize safety and efficiency. Could it be time to take a closer look at your fume control strategies? Read our article published in the February issue of Fabricating & Metalworking. For the past 40 years, 4-Star Trailers in Oklahoma has built high-quality aluminum stock and horse trailers. Aluminum is lightweight, corrosion-resistant, and strong—ideal for trailers designed to endure tough road conditions. However, welding aluminum with a push-pull gun has its challenges. The heaviness of the tool can make it difficult to maneuver in tight angles, and the added weight can lead to welder fatigue, especially when working on large parts or frames. Additionally, this setup can cause delays in production timelines due to discomfort and inefficiency during long hours of use. Before switching to the Bernard® BTB Semi-Automatic Air-Cooled MIG Gun, the team regularly faced feeding issues. The feeding problems were especially noticeable when working on large aluminum parts, causing disruptions and affecting their ability to keep up with demanding production schedules. The difficulty in maneuvering the push-pull gun, coupled with the physical strain it placed on welders, contributed to frequent delays and a slower pace of work. The BTB Gun has been a game-changer. It pushes aluminum wire long distances with ease, something that wasn’t possible with the previous system. Its design is lightweight and maneuverable, making it far easier for welders to handle, especially in tight spots. This has significantly reduced fatigue, allowing the team to work longer and more comfortably without sacrificing quality. The customizable neck lengths of the BTB Gun are another huge advantage, allowing welders to reach into tight angles or handle bigger components with greater ease. The Easy Feed Liner in the BTB Gun reduces friction, making it simpler to feed aluminum wire and minimizing downtime—critical for maintaining a steady workflow in a busy shop. With fewer interruptions, the team is able to stick to production goals and meet deadlines more effectively. The use of AccuLock consumables also contributes to less maintenance, as they last longer than other options, cutting down on the frequency of replacements and the time spent on maintenance tasks. The biggest benefit? The team is more productive and satisfied with their work. With fewer interruptions and smoother operations, they’re able to produce high-quality welds faster. The BTB Gun has not only made their jobs easier but also helped the business run more efficiently. It’s become an indispensable tool in their shop, enabling them to build even tougher, more dependable trailers while improving overall productivity and welder satisfaction. Bernard’s Clean Air E™ fume extraction MIG Gun helps create a cleaner and more productive welding environment by capturing up to 95% of fumes at the source, improving weld visibility, and reducing welder fatigue. Designed for durability in heavy industrial use, it minimizes rework, lowers compliance risks, and supports efforts to attract and retain top talent. Say goodbye to compromise and hello to precision, performance, and peace of mind. It Starts At The Source™ Learn more: https://www.startsatthesource.com Discover the Clean Air E™ difference. Superior Fume Control Right at the Source With up to 95% source fume capture efficiency, the Clean Air E minimizes airborne contaminants, protects your team, and improves visibility on every weld. It helps you meet stringent compliance standards without compromise. Effortless Ergonomics for Extended Use Designed for welders, the Clean Air E features a balanced build, optimized handle design, and a ball swivel for added flexibility. This reduces strain and improves control, focusing on comfort and efficiency to help welders stay productive through long shifts. Industrial-Grade Durability, Reduced Downtime Built for heavy-duty use, the Clean Air E is engineered to last. Its rugged design, combined with long-life consumables, reduces maintenance demands and lowers total costs, keeping your team welding without interruption. Enhanced Visibility for Precise Welds Clearer sightlines mean better welds. The Clean Air E is designed to minimize arc obstructions, providing improved visibility and weld access. With a better view of the weld puddle, welders can work with greater accuracy, control, and consistency. Want to learn more? Click here. The New Clean Air E™ Fume Extraction MIG Gun Offers Superior Fume Capture, Enhanced Ergonomics

The New Clean Air E™ Fume Extraction MIG Gun Offers Superior Fume Capture, Enhanced Ergonomics

Up to 95% fume capture efficiency and optimized design make workspaces safer and reduce welder strain

Product Guide: Clean Air E™ – Changing the Y Connector

Product Guide: Clean Air E™ – Changing the Y Connector

Product Guide: Clean Air E™ – Connecting to a Fume Extraction Unit

Product Guide: Clean Air E™ – Connecting to a Fume Extraction Unit

Product Guide: Clean Air E™ – Replacing the Neck and Trigger

Product Guide: Clean Air E™ – Replacing the Neck and Trigger

Product Guide: Clean Air E™ – Changing Shrouds to Maximize Fume Extraction

Product Guide: Clean Air E™ – Changing Shrouds to Maximize Fume Extraction

Product Guide: Clean Air E™ – Changing Out the Hose

Product Guide: Clean Air E™ – Changing Out the Hose

The Importance of Implementing a Layered Approach to Fume Mitigation

The Importance of Implementing a Layered Approach to Fume Mitigation

Bernard® BTB Gun Transforms Aluminum Welding for 4-Star Trailers

Bernard® BTB Gun Transforms Aluminum Welding for 4-Star Trailers

Introducing Clean Air E™

Introducing Clean Air E™

Features and Benefits of the Clean Air E™

Features and Benefits of the Clean Air E™