Bernard and Tregaskiss offer various rear load, innovative front load, and other revolutionary MIG welding liner solutions. Wondering what liner is right for your MIG gun? Check out our MIG Liner Compatibility Chart.

E-Z Feed Liners

Built Tough To Feed Smooth.

- These liners feature a corrosion resistant coating and a unique enhanced coil profile that reinforces rigidity and wire support. The result is smoother, more consistent wire feeding, even in the most challenging applications such as stainless steel, metal core, or pushing aluminum.

Front Load Liners

Load and Lock for Better Productivity

- Flawless wire-feed path – An essential component of the complete AccuLock S consumables system, front load liners are locked and concentrically aligned to both the contact tip and the power pin.

- Error-proof liner replacement every time with no measuring!

QUICK LOAD® Liners

Load your liners from the front of the MIG gun in less than half the time it takes to install conventional liners.

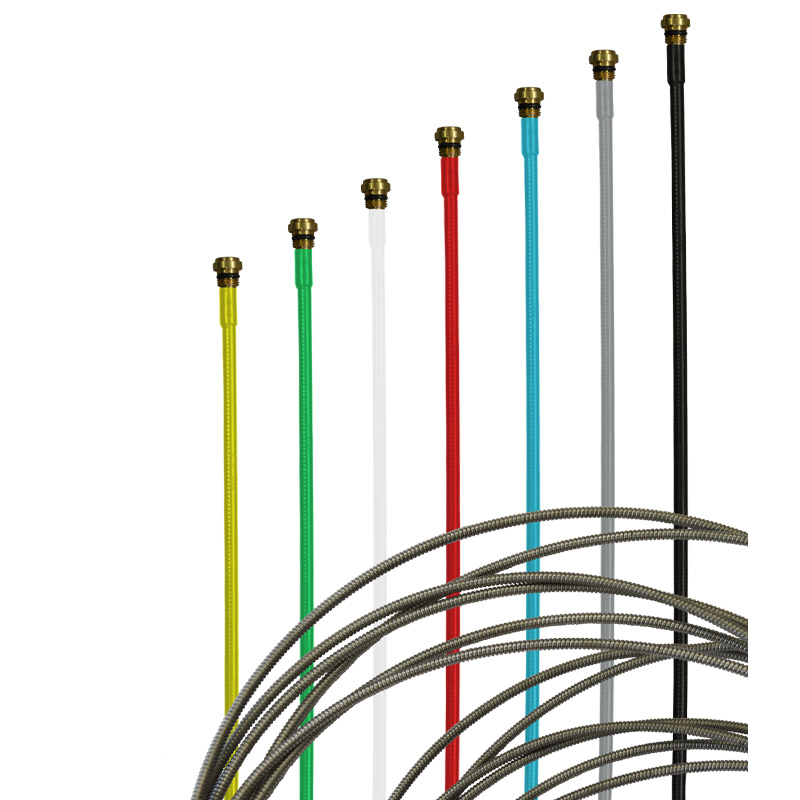

Bernard® Rear Load Liners

- Simplify and reduce your inventory with Bernard® rear load liners

- Color-coded by wire size for ease of identification

- Made of high carbon music wire to achieve smooth wire feed and long life

- These rear-loading liners won’t gap when bent

Tregaskiss® Rear Load Liners

Ideal for aluminum, steel, stainless steel and flux-cored wire, rear load liners are made of high carbon music wire for smooth wire feed and long life.