4 Reasons Genuine Consumables Lead to Better MIG Welds

Welders must be able to rely on every aspect of their equipment, and consumables are an integral component of a high-quality weld. When you notice an uptick in downtime and consumables consumption, it’s time to take a deeper look at what the culprit could be. An easy place to start is by looking at the quality of the consumables you’re using. Lower-quality consumables can lead to major expenses in the long run — as seen in lost production, weld rework and the cost of constant replacements.

Original equipment manufacturer (OEM) consumables are the right choice for improved operations and consistent, high-quality welds. Below are four reasons you should consider investing in genuine consumables over lower-quality options.

- Consumable quality affects your performance

Even the best MIG guns or the most highly trained operators cannot offset the impact of poorly made consumables on performance. OEM consumables are manufactured using high-quality materials, which helps deliver the arc stability needed to create smooth, even welds with minimal defects. In addition to helping improve weld integrity and facilitating more durable weld joints, genuine consumables also help prevent excessive spatter and minimize post-weld cleanup.

Because OEM consumables are manufactured for reliability, they have consistent diameters and surface conditions that ensure smoother feeding through the gun. By contrast, non-genuine consumables are often made from low-quality materials and may not consistently meet key manufacturing specifications.

2. OEM consumables are expertly designed to be reliable

Genuine consumables are backed by research, technology and expertise, having been produced to ensure the material composition and mechanical properties are consistent and reliable. Keeping those details at the forefront makes for stable arcs, high-quality welds, fewer points of failure and simplified maintenance. Their ease of use can even help to reduce welder training times and shorten your troubleshooting list if problems do arise.

Copycat manufacturers are also less likely to submit their consumables to the rigorous testing and quality assurance processes that OEMs follow.

AccuLock ™ consumables have been designed to flawlessly integrate into Bernard® semi-automatic and Tregaskiss® fixed automatic and robotic MIG welding guns and to address welders’ most common pain points.

For semi-automatic MIG welding applications, the AccuLock™ S consumables system paired with front load E-Z Feed™ liners reduces liner trim length errors and erratic wire feeding while simultaneously increasing contact tip life. The front load liners are locked and concentrically aligned to both the contact tip and power pin. This eliminates misalignment and provides a flawless wire feed path, ensuring uninterrupted delivery of the wire to the weld puddle. As a result, operators have fewer burnbacks, bird nests and erratic arcs.

The AccuLock R consumables system is available for robotic or fixed automatic MIG welding applications. With these consumables, operators have the opportunity to realize significant improvements, like increasing contact tip life span and decreasing issues with contact tip cross-threading.

For operations constantly managing complex or costly consumables inventories, AccuLock S and AccuLock R consumables systems share a common contact tip — making for simplified part inventory across mixed fleets of semi-automatic and automated welding applications. Operations who are looking to get more life out of their consumables but aren’t using Bernard or Tregaskiss guns can purchase the conversion series consumables to still experience the benefits of a high-quality system.

3. Using low-quality products limits your manufacturer’s ability to help

A good OEM is invested not only in the performance of its products but also in the overall user experience, which extends to customer service. Reputable OEMs usually have expert technical support teams that help with troubleshooting and provide solutions if something goes wrong. They can also share product tips and offer advice, like how to make your MIG gun consumables last longer.

However, if you’re using nongenuine consumables and parts, technical support teams are unable to offer such assistance. Often, if an issue arises involving lower-quality parts, it will be essential to order genuine parts and wait for them to arrive to see if the issue still occurs before the OEM team can offer support. Using genuine parts from the get-go means you can get expert advice right away — or avoid issues altogether.

4. OEM products can have a longer life

Because OEMs are making greater investments in materials, design and testing, that means OEM consumables usually cost more than low-quality consumables. But, as the saying goes, you get what you pay for. Consumables are probably not your biggest cost — labor is. So any money you save by using cheaply made consumables could be offset by the extra labor required to frequently change tips, troubleshoot equipment failure or rework a faulty weld. Those looking for superior performance and longevity find that OEM options can equate to more arc-on time — and more products out the door.

AccuLock contact tips are designed so that 60% of the tip is buried within the diffuser for less exposure to the heat of the arc and more cooling from shielding gas. This gives the tip a life that can be two to three times longer than other tips.

All told, because genuine consumables are designed specifically for your MIG welding gun, they can last longer, be more reliable and deliver higher-quality welds — ultimately enhancing the operator experience and your welding operation’s bottom line.

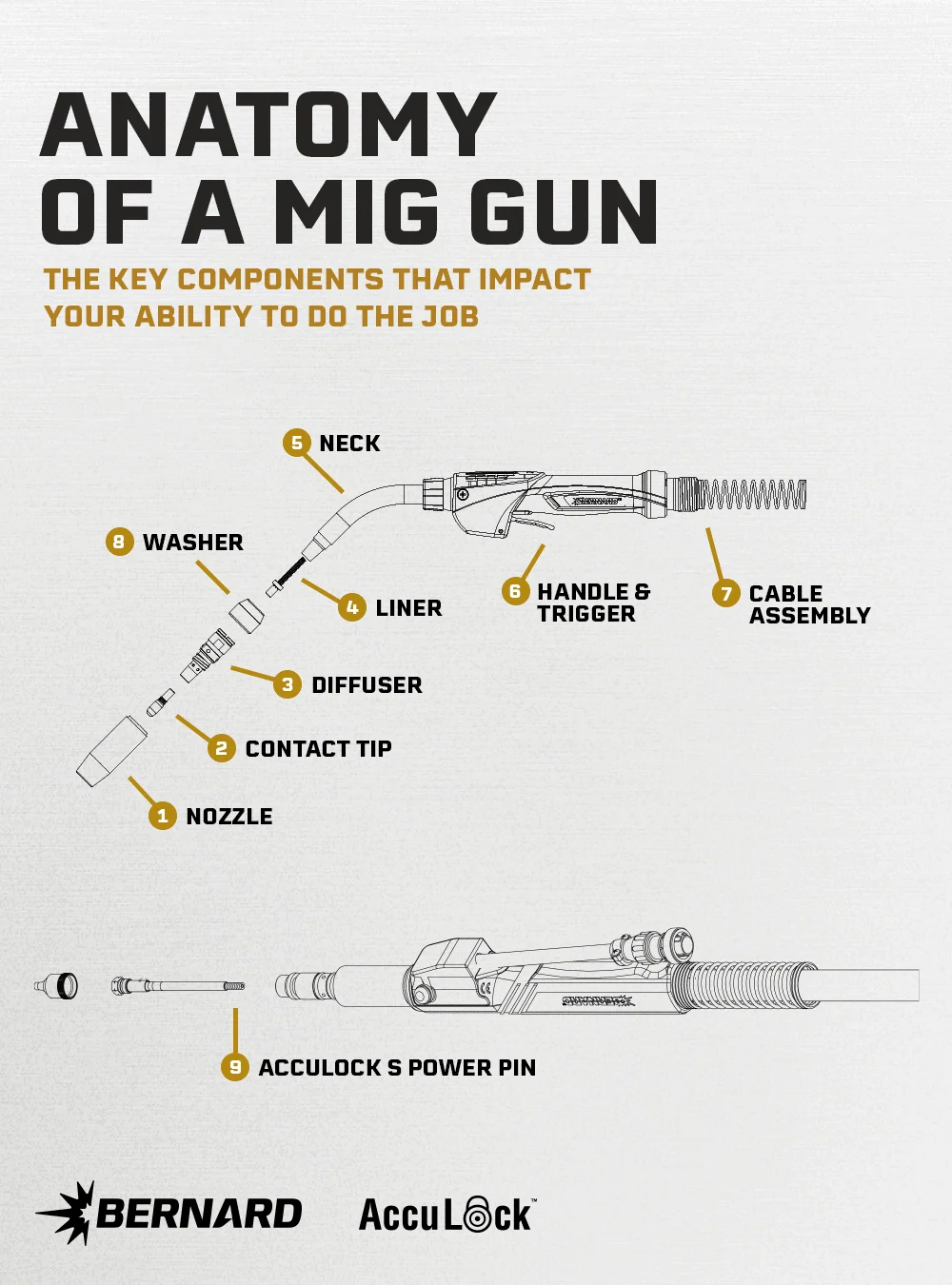

Key MIG Gun Components for Job Performance

Key MIG Gun Components for Job Performance

MIG welding is a common welding process especially useful for beginner and DIY welders due to its easy-to-learn nature, shorter lead times and lower production costs. The versatility of MIG welding allows users to work on a wide range of materials with less stopping and restarting. The process features a continuous consumable wire electrode being fed through a welding gun and into a weld pool. The gun also feeds a shielding gas alongside the wire to protect the weld pool from contaminants.

While there are different types of MIG guns that have unique parts (e.g., water-cooled, air-cooled, fume extraction), all MIG guns have some parts in common. Understanding the components of a MIG gun and the process by which it works will help you make decisions on the consumables and gun type you select for your job. Here’s what you need to know.

CONSUMABLES

1. Nozzle

- The nozzle directs the shielding gas to cover the weld puddle.

- By shielding the weld puddle, the nozzle helps to prevent spatter on the weld surface while simultaneously protecting internal components of the gun from heat and spatter.

2. Contact Tip

- The contact tip guides the wire and transfers the current from the neck through the filler metal and to the work surface. Consistent wire feeding ensures a stable arc and high weld quality.

3. Diffuser

- The diffuser conducts electricity to the contact tip while dispersing gas evenly across the weld pool.

- Ensuring even distribution of shielding gas ensures consistent coverage of the weld pool, preventing contamination and defects like porosity and oxidation.

4. Liner

- The liner is crucial to MIG welding because it guides the wire electrode from the wire feeder through the cable to the contact tip.

- A worn or low-quality liner can cause friction, leading to inconsistent feeding and arc instability and, ultimately, poor weld quality.

- There are several materials of liners for consideration, each with advantages in different applications.

ESSENTIAL GUN COMPONENTS

5. Neck

- The neck is the front-end extension of a MIG welding torch and houses vital components like the contact tip, gas nozzle and wire feeder inlet.

- It directs the welding arc and shielding gas precisely onto the weld joint, improving weld quality and consistency.

- Selecting the right neck (i.e., long versus short) is important because it impacts a welder’s posture, visibility and heat control.

6. Handle and Trigger

- The handle and trigger impacts how long an operator can weld without experiencing fatigue.

- Handles with an ergonomic design and a natural feeling grip will improve operator comfort and welding duration.

- When selecting a trigger, it needs to be responsive to the touch and best suited for the job (e.g., multi-schedule, locking).

7. Cable Assembly

- In MIG welding, the cable assembly delivers power, gas, filler metal and control signals to the welding gun.

- Without the successful transmission of each of these elements, the weld will not function as intended.

- Compression fittings are an integral aspect of the assembly because they provide a reliable connection, better energy transfer and less resistance.

OTHER COMPONENTS

8. Insulator

- Plays a critical role in electrical isolation and heat management.

- Made of a non-conductive material to help electrically isolate the metal components of the welding gun (e.g., the trigger mechanism) from the electrical circuit carrying the welding current.

- Acts as a thermal barrier between nozzle and trigger mechanism, preventing overheating and malfunctions.

9. Power Pin

- Power pins provide a direct connection for wire, weld power and gas flow between the welding machine and/or wire feeder and the MIG gun. An accurate gun-to-machine connection is critical to ensure that the filler wire, gas and weld power are passed efficiently to the gun.