How the Bernard® IronPro™ Keeps Trains on Track at CSX Transportation

In Atlanta, Georgia, CSX Transportation keeps 1,848 trains running every day; a demanding job where every minute of downtime matters. Fast, reliable repairs are critical to keeping operations on track.

Before switching to the Bernard IronPro, CSX welders faced constant challenges. The intense heat of track repairs was tough on their old welding guns, which weren’t built to handle the job’s demands. Wire bird-nesting and other issues slowed them down, making it hard to keep up with repairs.

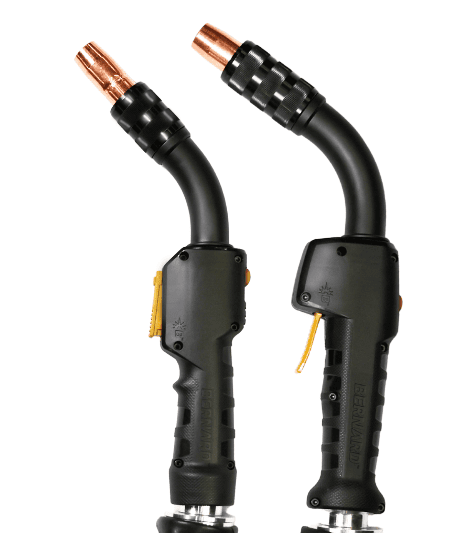

The IronPro changed that. Built for heavy-duty work like construction, shipbuilding, and equipment repair, it’s tough enough for the high-pressure environment of railroad track welding. With up to 450 amps of power, it delivers consistent, reliable welds even under the most extreme conditions.

Comfort is another reason welders love the IronPro. Its lightweight, slim neck design makes it easier to work in tight spaces on the tracks while reducing strain during long shifts. Less fatigue means the team can stay focused and get more done.

The gun’s versatility is a big plus too. Customizable neck lengths and other options make it easy to adapt to whatever challenges come up in on the tracks.

Since switching to the Bernard IronPro, CSX has cut downtime, sped up repairs, and kept their trains running on schedule. For the welders, it’s become a go-to tool they can depend on every day to get the job done right.

Learn more about the Bernard IronPro.

E-Z MIG Liner Guide

E-Z MIG Liner Guide

Mastering MIG welding liners: Types, challenges and solutions

Liners play a critical role in welding gun performance, directly impacting the quality and efficiency of the welding process. A smooth and consistent wire feed is what facilitates a stable arc and the ability to achieve uniformity of the weld. The choice of liner depends on factors such as the welding wire diameter, the type of material you’re welding and the specific MIG welding setup you’re using. There are several types of liners available, each with their advantages and disadvantages.

Rear-loading liners:

Rear-loading liners are installed through the back of the gun and are frequently used in the industry, so many welding operators are already familiar with and comfortable installing this type of liner. It is important that these liners are trimmed to a length compatible with cable length and consumable style to avoid feeding issues. Even if trimmed correctly, rear-loading liners can move from optimal position behind the contact tip as the cable grows and shrinks with twisting, potentially leading to the liner not being seated properly inside the retaining head.

Front-loading liners for handheld welding:

Bernard® front load liners are designed to address liner trim length errors, gaps along the wire-feed path and erratic wire feeding. They lock and concentrically align to both the contact tip and the power pin, and the lack of measuring guarantees error-proof liner replacement every time. These can only be used with the AccuLock® S consumables system.

Front-loading liners for automation:

QUICK LOAD® liners require less than half the time and effort to replace compared to rear load liners. After initial installation, QUICK LOAD liners minimize downtime by eliminating the trouble of maneuvering around tooling or transferring systems to remove the MIG gun from the wire feeder. It also allows for liner changeover from a safe zone outside the work cell during routine pauses in production.

Polymer liners for aluminum:

MIG welding guns for aluminum typically use polymer liners because they provide a smooth, low-friction path for the soft aluminum wire, reducing feeding issues. However, these liners are more delicate and wear out faster, making them less durable for heavy-duty applications.

Choosing the right liner is an important detail and can be the difference between costly interruptions and efficient welding performance.

MIG welder liner challenges that impact performance

While welding liners can arguably be seen as one of the more important components to a welding setup, they’re commonly seen as the hardest consumable to troubleshoot. Changing a liner requires turning off equipment, sometimes disconnecting the gun, and removing the liner — steps that lead to significant downtime. As a result, welders often replace nozzles, tips or diffusers first because they’re easier to access. That can temporarily mask liner-related problems but doesn’t solve them long-term. The most common problems associated with liners include:

Birdnesting:

Various characteristics of a liner can contribute to birdnesting, making it a delicate balance to strike. Excessive debris inside the liner can also restrict movement, causing inconsistent feeding. In cases of debris buildup, it is sometimes possible to restore functionality by removing the wire and purging the liner with compressed air without detaching it from the cable assembly.

The length and inside diameter of a liner can also impact how a wire travels through it. A liner that’s too short creates gaps, and one that’s too long compresses the wire path. Similarly, a liner that has an inside diameter too large for the wire in use may not adequately support the wire as it travels through the liner. One that is too tight increases friction and resistance. All of those discrepancies open the door for the wire to become tangled and unmanageable. Ultimately, not only does it take time to fix the wire (and potentially change the liner), but the wasted wire and downtime can drive up operational costs.

Poor wire feeding:

Erratic or irregular wire feeding may occur simply as a result of localized wear. When wear is evident, liner replacement is typically required to ensure consistent wire delivery and maintain welding performance.

Installation and trim length errors, which includes trimming the liner too short or having a liner that is too long, especially with rear load liners, can cause wire feed issues.

Kinks or bends in the cable:

Handheld welding typically involves longer power cables, which increases friction and makes wire feeding more difficult. Coiled or twisted cables further exacerbate these issues.

Innovative liner design helps overcome common welding challenges

To help alleviate common welding liner issues, E-Z Feed™ liners were engineered to reduce friction, reinforce rigidity and broaden compatibility in one solution. They’re available as rear-load, front-load and QUICK LOAD options, which are designed for automated setups, to help tackle any welding setup. The E-Z Feed liner stands out for several reasons:

Superior wire feeding:

It’s especially effective with softer, hard-to-feed wires like cored wire and aluminum, as well as common solid wires. Its design minimizes friction and supports smoother, more consistent wire delivery.

Corrosion-resistant coating:

This coating reduces friction, protects against corrosion and extends liner life.

Enhanced coil profile:

Reinforces rigidity and wire support, further improving wire feed reliability.

Versatility:

Initially engineered to solve problems related to cored wire, E-Z Feed liners have proven effective across all wire types, including aluminum and stainless steel.

Improved value:

The durability and performance reduce downtime and consumable replacements, resulting in long-term savings.

E-Z Feed liners are backward compatible with existing Bernard guns, and installation method is the same as a similar rear load or front load liner, making upgrades straightforward. Because of their performance benefits, E-Z Feed liners are now included as standard with every Bernard BTB MIG gun.

For MIG welding, the right liner can be a true performance driver. Liners may seem like a small component, but their impact on wire feed consistency, arc stability and overall welding performance is significant. Optimized for versatility, E-Z Feed liners help welders gain consistency and confidence across a wide range of job types and conditions. Choosing an innovative solution like this helps mitigate common frustrations and keep productivity moving forward.

Want to optimize your tools?

Check out the E-Z Feed Liner Page to see compatibility.

Vactor’s Formula for Better Welding

Vactor’s Formula for Better Welding

Building vacuum trucks that keep cities running is no small task.

For Vactor Manufacturing, a leader in sewer cleaning and vacuum excavation equipment, every weld matters. These trucks face demanding environments, so durability and precision during production are critical.To meet the demands of heavy-duty welding, Vactor relies on Bernard® BTB MIG Guns and AccuLock™ consumables. This combination helps them:

- Maintain uptime with quick-change liners and long-lasting contact tips

- Improve weld quality for large steel components

- Simplify maintenance and reduce downtime

These solutions keep Vactor’s production moving and their trucks ready for the toughest jobs.

Want to optimize your tools?

Check out the BTB MIG Gun Configurator to configure a gun that works with your operation, so you can weld it right the first time.

Learn More about Vactor Manufacturing

Vactor Manufacturing, based in Streator, Illinois, is a leading provider of sewer cleaning and vacuum excavation equipment. With over 50 years of expertise, Vactor has pioneered innovations like the first combination sewer cleaner and continues to deliver durable, reliable machines that help communities maintain critical infrastructure safely and efficiently.

Right-the-First-Time Welding

Right-the-First-Time Welding

Fixing defects demands careful planning and expert execution

Welding repairs often involve higher

stakes than original fabrication. The

pressure is greater, the conditions

are more challenging, and the consequences of

failure are more severe. Once a critical weld is

compromised, the risks increase significantly:

What was critical becomes supercritical, the

margin for error narrows, and the cost of

failure multiplies. A failure in a newly fabricated

pressure vessel might be inconvenient, but a

failure in a repaired pressure vessel already in

service could be catastrophic…

Read the full article here.

Want to optimize your tools?

Check out the BTB MIG Gun Configurator to configure a gun that works with your operation, so you can weld it right the first time.

About the Author

Mostafa Hanafy

Mostafa Hanafy (mostafa.hanafy@bernardtregaskiss.com) is director of strategic marketing and product management at Bernard and Tregaskiss.

Automation for Better Welding

Automation for Better Welding

Technology enhancements optimize and advance automated welding performance.

The skilled labor shortage is not a new concern within the welding industry. While efforts are being made to attract new talent, those who join still need ample time to learn and truly refine their skills. Because of shortages and the lengthy on-ramps for newer welders, some operations may still be behind in meeting the demands of their business and struggling with weld quality and consistency issues…

Read the full article here.

Want to optimize your operations?

Check out the Atlas Data Sheet to see how it can improve uptime and minimize training efforts.

To learn more about upgrading your automation efforts visit the Atlas Robotic ThruArm MIG Torch Product Page here.

About the Author

Brad Whipple

Brad Whipple is a senior engineer for Tregaskiss. Email brad.whipple@bernardtregaskiss.com

Right Equipment, Better Ergonomics

Right Equipment, Better Ergonomics

A welder that can keep comfortable doing the job is likely to avoid unnecessary strains

It’s no surprise that as welders reach their 30s, they are not as flexible and limber as they were when they were just starting out in the metal fabricating business. What is surprising is that most companies don’t take that into account, putting these valuable craftsmen at risk of possibly developing sprains and strains that make them unable to work.

These types of ergonomic injuries—pain and damage to muscles, tendons, and ligaments caused by awkward positions and repetitive activities—are real factors in the manufacturing industry. According to the Bureau of Labor Statistics….

Read the full article here.

At Bernard Welding, we place a strong emphasis on welder comfort and ergonomics in every product we release.

By configuring your own MIG gun, you can customize it to fit the way you work—rather than adjusting the way you work to fit the tool. Use our configurator to design a Bernard MIG gun that helps your welders stay comfortable, weld longer, and work more productively; so they can keep delivering quality parts for years to come.

About the Author

Dan Davis

Editor-in-Chief

2135 Point Blvd.

Elgin, IL 60123

815-227-8281

Dan Davis is editor-in-chief of The Fabricator, the industry’s most widely circulated metal fabricating magazine, and its sister publications, The Tube & Pipe Journal and The Welder. He has been with the publications since April 2002.

A Big Win for Clean Air E – Bernard Takes Home a Pro Tool Innovation Award!

A Big Win for Clean Air E – Bernard Takes Home a Pro Tool Innovation Award!

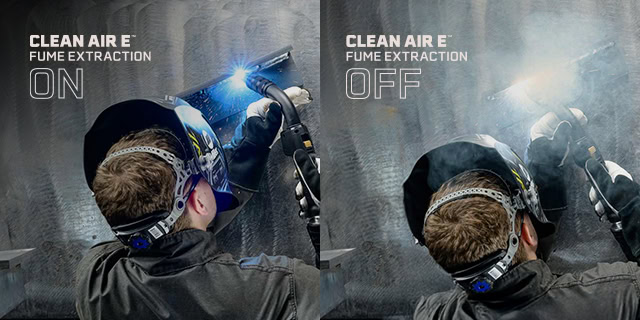

Bernard® Clean Air™ E fume extraction gun has been recognized with a 2025 Pro Tool Innovation Award in the Automotive and Metalworking category, under Welding Guns.

The Pro Tool Innovation Awards are judged by a panel of contractors, trade professionals, and tool experts who evaluate products based on innovation, performance, and value. These awards highlight tools that solve real jobsite challenges and help professionals work more efficiently. Winning products are selected for their ability to improve workflow, boost productivity, and offer new opportunities in the field.

The Automotive and Metalworking category includes tools built for those working with metal or vehicles. It covers everything from welding guns and grinders to inspection tools and accessories. Clean Air E stood out for its ability to deliver cleaner air, better ergonomics, and long-term durability. These key benefits are all critical for demanding industrial environments.

What Makes Clean Air E Different

- Fume Control at the Source – Efficient Extraction

Clean Air E captures up to 95% of weld fumes directly at the arc. This helps protect welders, improves visibility, and supports compliance with health and safety standards. - Comfort That Lasts – Enhanced Ergonomics.

Designed with welders in mind, it features a balanced build, optimized handle, and ball swivel for better control and reduced fatigue during long shifts. - Built to Handle Tough Jobs – Engineered for Endurance.

Its rugged design and long-life consumables reduce downtime and maintenance, keeping operations running smoothly. - Improved Visibility for Better Welds

The gun is engineered to minimize arc obstructions, giving welders a clearer view of the weld puddle for more precise and consistent results.

This award is a reflection of the hard work and collaboration across our team. From product development to launch, everyone played a role in making Clean Air E a success.

You can view the full list of winners at protoolinnovationawards.com.

Interested in the Bernard Clean Air E?

Tregaskiss Redefines Performance With New Atlas™ Robotic ThruArm Air-Cooled MIG Torch

Tregaskiss Redefines Performance With New Atlas™ Robotic ThruArm Air-Cooled MIG Torch

Engineered for precision, built for uptime and designed to hit your mark

BEECHER, Ill./WINDSOR, Ontario (September 4, 2025) — Tregaskiss, a leading innovator in robotic welding solutions, introduces the Atlas™ robotic MIG welding torch — a next-generation, air-cooled ThruArm GMAW torch engineered to deliver unmatched efficiency, repeatable precision and simplified maintenance. Constructed to endure the demands of industrial environments, Atlas helps operators reduce downtime by up to 87% while ensuring consistent, high-quality welds.

Atlas raises the bar in robotic MIG welding and delivers a breakthrough in uptime and weld quality. Its robust construction and streamlined cable routing minimize unplanned downtime and maintenance, while producing high-quality welds across demanding applications.

“We took over three decades of experience and know-how in robotic MIG welding and unleashed our engineers to develop this revolutionary and innovative robotic A/C thru-arm torch,” said Andrew Marchand, director of engineering. “As a result, Atlas sets a new standard in the industry for installation time, TCP repeatability and ease of maintenance.”

Ideal for operations focused on automotive, heavy equipment and general manufacturing, Atlas sets a new standard with its toughness and accuracy. Key features and benefits include:

- Consistent tool center point (TCP): The keyed stainless steel neck construction provides superior rigidity, long-lasting positional features and increased neck-to-neck repeatability. Additionally, the isolated, separate mechanical and electrical functions, combined with a direct neck-to-cable connection, reduce performance issues.

- Maximized uptime: Tool-less cable change, predictive maintenance indicators and quick-change components reduce unplanned downtime and total service time.

- Designed for durability: Built tough to withstand harsh industrial environments, Atlas protects key components from debris and spatter and extends torch life.

- Streamlined maintenance: Intuitive features like captured fasteners, inspection windows and install confirmation indicators make servicing fast and foolproof.

- Engineered efficiency: The modular, optimized design drives better performance and simplifies training and maintenance.

The Atlas torch will officially debut at FABTECH 2025 this September, where attendees can experience its performance firsthand. Visit booth B20027 from September 8-11 to learn more about Atlas and how it can transform your robotic welding operations.

If you can’t attend the show, visit https://www.bernardtregaskiss.com/product/atlas/ for additional details.

About Tregaskiss

Tregaskiss is a trusted manufacturer of high-quality robotic MIG welding torches and consumables, focused on delivering performance, reliability, and efficiency in automated welding applications. Based in Windsor, Ontario, Tregaskiss designs innovative solutions that offer durability for industrial applications, support system uptime, and reduce maintenance needs in demanding environments. Tregaskiss is a proud brand of Illinois Tool Works Inc. (NYSE: ITW). For more information, visit BernardTregaskiss.com, call 1-855-MIGWELD (1-855-644-9353), or email CS@itwmig.com.

Contact:

Lauren Smith, Hiebing for Bernard/Tregaskiss

phone: +1 6082684408

Contact: Lauren Smith, Hiebing for Bernard/Tregaskiss phone: +1 6082684408 lsmith@hiebing.com

The Hidden Cost of Cutting Corners in Robotic Welding Equipment

The Hidden Cost of Cutting Corners in Robotic Welding Equipment

The global robotic welding market is heating up. This growth is being fueled by a critical mix of factors: a shortage of skilled welders, the rising demand for manufacturing efficiency, and an industry-wide push toward automation across sectors like automotive, aerospace, construction equipment, and general fabrication.

At the center of many robotic welding cells is MIG welding, prized for its speed, adaptability, and suitability for automation. But what often gets overlooked in the race toward automation is this: your system is only as good as the equipment you put into it.

And cutting corners on that equipment? It comes with a price.

Downtime Is Expensive and Often Avoidable

Cheap or underperforming components can quickly turn a high-output robotic welding cell into a bottleneck. From unreliable torches to inconsistent consumables, even minor issues can lead to misaligned welds, excessive spatter, or system stoppages that eat into productivity. Worse yet, these problems are rarely one-offs. Poor-quality components often result in frequent rework, more operator intervention, and additional maintenance all of which erode your ROI over time.

Repeatability and Reliability Shouldn’t Be Optional

Robotic systems rely on repeatable precision. Every weld pass, programmed path and every contact point needs to perform the same, shift after shift. That’s nearly impossible to achieve if your equipment isn’t built to hold tolerances or endure tough environments.

Newer torch designs, like the Tregaskiss® ATLAS™ Robotic ThruArm MIG Torch, have been engineered to deliver consistent, repeatable performance in even the most demanding applications. While not the only solution, products like this are helping manufacturers cut down on downtime and reduce the need for frequent reprogramming or adjustments.

Skilled Labor Is Scarce – Simplicity Matters

With fewer experienced welders and technicians entering the workforce, maintenance routines need to be simplified and, ideally, predictable. Equipment that requires constant tweaking or is difficult to service adds stress and inefficiency to an already stretched workforce.

Modern robotic welding gear is starting to address this. Atlas™ addresses the pain behind predictive maintenance and visual inspection features to take the guesswork out of service intervals. Compatibility with the Tregaskiss Torch Maintenance Module, for instance, allows teams time for maintenance before failure occurs – not after. That kind of visibility leads to fewer unexpected stoppages, fewer errors during maintenance, and more time spent where it counts: welding parts.

The Real Cost Isn’t Just Dollars – It’s Lost Opportunity

In a fast-moving manufacturing environment, the true cost of cutting corners isn’t just found on a balance sheet. It’s in jobs that don’t ship on time. The customers who look elsewhere. The employees are frustrated by constant issues.

Choosing the right robotic welding equipment from the start, even if it comes with a slightly higher price tag is an investment in long-term stability, performance, and productivity. It’s about building a system that works with your team, not against it.

Quality Pays for Itself

As robotic welding continues to expand across industries, the companies that will lead the charge are those who recognize that good equipment isn’t a luxury, it’s a necessity. Whether it’s a rugged torch that stands up to tough environments, or consumables designed for long life and precision, choosing quality upfront prevents pain later.

And in today’s climate of labor shortages, rising expectations, and constant pressure to do more with less, that choice might just be the difference between staying competitive, or falling behind.

Learn more about how Atlas can help save your operation time and money.

GET STARTED.

Improved Flux-Cored Welding for Heavy-Duty Field Use

Improved Flux-Cored Welding for Heavy-Duty Field Use

Understanding operator challenges is what drives innovation in the welding industry. For some, that challenge is outdoor welding, where using shielding gas is not optimal. In these extreme conditions, traditional MIG welding won’t necessarily work. Turning to a different process, such as self-shielded flux-cored welding (FCAW-S), allows for more effective welding in the field. When welding in harsh environments, operators require durable, rugged equipment that can withstand the elements and the nature of the work.

Operators utilizing self-shielded flux-cored welding demand a high level of flexibility and reliability in their equipment, which is why Bernard optimized the IronPro™ self-shielded FCAW gun to be extremely durable when welding in heavy-duty field operations.

Features that enhance flux-cored welding for heavy-duty applications

Operators need a gun that stays cooler in the hand and is lightweight, portable and reliable — handling the rigor of the toughest worksites while improving operator comfort. To improve usability and the overall user experience, IronPro introduces several enhancements to meet those needs and help overcome technical and operational challenges when out in the field.

Specifically, the IronPro 350 has a 350-amp rated output with a 60% duty cycle, making it ideal for operators working in construction, shipbuilding and heavy manufacturing. The design was further updated to include:

- Interchangeable neck options: The IronPro 350 features two rotatable neck options — one that’s 7 inches with a 60-degree bend radius and one that’s 12 inches with a 45-degree bend radius. These allow operators to ergonomically access even the most challenging, out-of-position welds. The neck can be rotated for a trigger-on-top approach, allowing for even more dexterity and customization at the joint.

- Sealed trigger: The trigger is designed to keep the area slag- and spatter-free, reducing maintenance downtime. Being non-metallic, it absorbs less heat, and it’s made with a sealed switch that helps keep out dust and dirt, leading to a longer lifespan.

- Lighter cable: The weight and bulk of higher amperage gun cables can lead to fatigue over extended periods of time. The cable for the 350 is lighter, making it more mobile and user-friendly for a welder on a day-to-day basis.

Incorporating all the updated design features mentioned above, IronPro 450 is also available for higher amperage applications, supporting up to 3/32″ wire size. IronPro 450 has a 450-amp-rated output with a 60% duty cycle.

Additional ways to improve field performance

To keep operators welding in tight positions longer, using AccuLock™ S consumables will increase contact tip life, resulting in fewer tip changes and increased overall performance with fewer points of failure. To further improve field performance, the cable liner incorporates Bernard® E-Z Feed™ technology, ensuring a reliable and smooth feed, minimizing chatter and poor arc characteristics. The superior feeding performance, paired with high-quality consumables, leads to more consistent welds, minimizing rework.

The tip insulator was redesigned to be more durable, withstanding more aggressive weld parameters to keep the electricity from short-circuiting between the tip and neck. Additionally, the insulator transitioned from being a slip-on to a thread-on, allowing it to stay in place better. These design improvements help minimize bridging from spatter and improve operator safety by ensuring the contact tip remains isolated to allow current to flow correctly through the wire to the weld puddle. Operators can choose between composite tip insulators, for increased joint access, or armored tip insulators, which are well-suited for higher amperage applications. These options allow operators to better customize their IronPro to suit the needs of their applications.

When welding heavy-duty applications in the field, operators need power, durability and consistency. The IronPro 350 offers improvements that exceed those demands. Welders can elevate their welding performance — and experience the productivity and quality benefits self-shielded flux-cored welding offers.

4 Reasons Genuine Consumables Lead to Better MIG Welds

4 Reasons Genuine Consumables Lead to Better MIG Welds

Welders must be able to rely on every aspect of their equipment, and consumables are an integral component of a high-quality weld. When you notice an uptick in downtime and consumables consumption, it’s time to take a deeper look at what the culprit could be. An easy place to start is by looking at the quality of the consumables you’re using. Lower-quality consumables can lead to major expenses in the long run — as seen in lost production, weld rework and the cost of constant replacements.

Original equipment manufacturer (OEM) consumables are the right choice for improved operations and consistent, high-quality welds. Below are four reasons you should consider investing in genuine consumables over lower-quality options.

- Consumable quality affects your performance

Even the best MIG guns or the most highly trained operators cannot offset the impact of poorly made consumables on performance. OEM consumables are manufactured using high-quality materials, which helps deliver the arc stability needed to create smooth, even welds with minimal defects. In addition to helping improve weld integrity and facilitating more durable weld joints, genuine consumables also help prevent excessive spatter and minimize post-weld cleanup.

Because OEM consumables are manufactured for reliability, they have consistent diameters and surface conditions that ensure smoother feeding through the gun. By contrast, non-genuine consumables are often made from low-quality materials and may not consistently meet key manufacturing specifications.

2. OEM consumables are expertly designed to be reliable

Genuine consumables are backed by research, technology and expertise, having been produced to ensure the material composition and mechanical properties are consistent and reliable. Keeping those details at the forefront makes for stable arcs, high-quality welds, fewer points of failure and simplified maintenance. Their ease of use can even help to reduce welder training times and shorten your troubleshooting list if problems do arise.

Copycat manufacturers are also less likely to submit their consumables to the rigorous testing and quality assurance processes that OEMs follow.

AccuLock ™ consumables have been designed to flawlessly integrate into Bernard® semi-automatic and Tregaskiss® fixed automatic and robotic MIG welding guns and to address welders’ most common pain points.

For semi-automatic MIG welding applications, the AccuLock™ S consumables system paired with front load E-Z Feed™ liners reduces liner trim length errors and erratic wire feeding while simultaneously increasing contact tip life. The front load liners are locked and concentrically aligned to both the contact tip and power pin. This eliminates misalignment and provides a flawless wire feed path, ensuring uninterrupted delivery of the wire to the weld puddle. As a result, operators have fewer burnbacks, bird nests and erratic arcs.

The AccuLock R consumables system is available for robotic or fixed automatic MIG welding applications. With these consumables, operators have the opportunity to realize significant improvements, like increasing contact tip life span and decreasing issues with contact tip cross-threading.

For operations constantly managing complex or costly consumables inventories, AccuLock S and AccuLock R consumables systems share a common contact tip — making for simplified part inventory across mixed fleets of semi-automatic and automated welding applications. Operations who are looking to get more life out of their consumables but aren’t using Bernard or Tregaskiss guns can purchase the conversion series consumables to still experience the benefits of a high-quality system.

3. Using low-quality products limits your manufacturer’s ability to help

A good OEM is invested not only in the performance of its products but also in the overall user experience, which extends to customer service. Reputable OEMs usually have expert technical support teams that help with troubleshooting and provide solutions if something goes wrong. They can also share product tips and offer advice, like how to make your MIG gun consumables last longer.

However, if you’re using nongenuine consumables and parts, technical support teams are unable to offer such assistance. Often, if an issue arises involving lower-quality parts, it will be essential to order genuine parts and wait for them to arrive to see if the issue still occurs before the OEM team can offer support. Using genuine parts from the get-go means you can get expert advice right away — or avoid issues altogether.

4. OEM products can have a longer life

Because OEMs are making greater investments in materials, design and testing, that means OEM consumables usually cost more than low-quality consumables. But, as the saying goes, you get what you pay for. Consumables are probably not your biggest cost — labor is. So any money you save by using cheaply made consumables could be offset by the extra labor required to frequently change tips, troubleshoot equipment failure or rework a faulty weld. Those looking for superior performance and longevity find that OEM options can equate to more arc-on time — and more products out the door.

AccuLock contact tips are designed so that 60% of the tip is buried within the diffuser for less exposure to the heat of the arc and more cooling from shielding gas. This gives the tip a life that can be two to three times longer than other tips.

All told, because genuine consumables are designed specifically for your MIG welding gun, they can last longer, be more reliable and deliver higher-quality welds — ultimately enhancing the operator experience and your welding operation’s bottom line.

Mastering MIG welding with adjustments, equipment and techniques

Mastering MIG welding with adjustments, equipment and techniques

Discover essential adjustments, equipment tips, and expert techniques to accelerate your MIG welding game by reading our article in the October issue of The Welder. You’ll learn how to balance voltage and wire feed speed for flawless welds, select the right welder and shielding gas, and master gun angle and travel speed. Plus, we’ll guide you through troubleshooting common challenges to ensure consistent, high-quality results. Don’t miss out on transforming your welding skills—dive into the full article now!

Introducing The Bernard® Clean Air E™

Introducing The Bernard® Clean Air E™

Welding professionals face daily challenges in keeping their work environment clean and safe. With strict weld fume regulations, effective fume control is more important than ever. The Bernard® Clean Air E™ fume extraction MIG gun helps by capturing welding fumes directly at the source without sacrificing performance.

Why Source Capture Matters

Capturing weld fume as close to the point of generation as possible, also known as source capture, is one of the most effective ways to reduce exposure. Unlike general ventilation or ambient air systems that dilute fumes, source capture methods like fume extraction guns immediately remove hazardous particles, helping improve air quality for operators and surrounding workers.

The Clean Air E™ captures up to 95% of fume at the source. The gun is built with adjustable extraction control through interchangeable shroud lengths and a slider allowing operators to fine-tune suction levels without affecting shielding gas coverage. This balance is critical for maintaining weld quality while maximizing fume capture.

Key Benefits of the Clean Air E™

Efficient Extraction

By removing up to 95% of fumes directly at the arc, the Clean Air E™ helps reduce exposure risks and contributes to a cleaner workspace.

Enhanced Ergonomics

With a lightweight handle design, the Clean Air E™ allows you to weld longer without fatigue. The ball swivel at the rear of the handle makes maneuvering easier, even in difficult positions.

Engineered for Endurance

This fume gun is built to withstand the toughest working environments. Made from durable, tested materials, it features a robust and straightforward design for easy maintenance.

Designed for Demanding Applications

Ideal for high-amperage and high-deposition rate applications, the Clean Air E™ is well-suited for industries such as: Shipbuilding, Heavy equipment manufacturing, General fabrication and manufacturing

Ergonomic and Easy to Use

Unlike bulky ventilation systems, fume extraction guns like the Clean Air E™ seamlessly integrate into a welder’s workflow. With a lightweight, ergonomic design and a user-friendly adjustment slider on the guns handle, it operates much like a standard MIG gun while providing the added benefit of fume extraction.

Customizable

We know every welder has their own preference when it comes to welding style. That’s why we designed two trigger options—a button and a lever, plus an extended lever for added comfort. We also made the shrouds interchangeable, offering three lengths to optimize either weld visibility or fume extraction, depending on your application.

A Smarter Step Toward Safer Welding

No single solution eliminates all welding fume exposure, but using a fume extraction gun alongside a compatible extraction unit like the Miller® Filtair®215 can significantly improve a workplace environment. The Bernard® Clean Air E™ provides a practical, effective way to prioritize welder safety and performance.

It starts at the source™

For Immediate Release BEECHER, Ill./WINDSOR, Ontario (March 20, 2025) — Bernard announced the release of the new Clean Air E™ fume extraction MIG gun, the newest high-efficiency fume extraction gun in the brand’s lineup. Crafted for efficient extraction, enhanced ergonomics and engineered endurance, this gun sets a new standard in MIG welding fume capture technology. With an ongoing priority to ensure safer, cleaner work environments for operators coupled with heightened fume standards being implemented across the country, Bernard saw an opportunity to evolve the standard fume extraction gun to maximize its efficiency and usability. Bernard took customer and welder feedback and designed a product that would be the most impactful for welders in a next-generation fume extraction gun. The team applied that feedback throughout the research and development process until it resulted in the Clean Air E™, which offers solutions to common operator pain points, including: · Efficient extraction: The Clean Air E™ achieves up to 95% fume capture right at the source, which improves air quality in the workspace and reduces OSHA-related risks. · Enhanced ergonomics: The ergonomic design reduces strain and fatigue on welders, which allows them to focus on precision and quality for extended use. · Engineered for endurance: The Clean Air E™ features durable components and long-life consumables, which reduces downtime and maintenance costs, delivering a lower cost of total ownership. “When it comes to welding, operators seek the trifecta in their gun: ergonomics, extraction performance and ease of maintenance,” said Jerome Parker, product manager, Bernard. “The Clean Air E™ was designed alongside actual users to ensure we arrived at a solution that redefined traditional fume capture guns for the modern welder, enhancing both their operator experience and their weld environment.” On the gun itself, the Clean Air E™ offers enhanced features for easier and more efficient use: · Improved weld access: Three nozzle shroud lengths allow operators to balance fume capture with weld access and improved visibility of the weldment. · Instant flow adjustment: The new flow control slide on the back of the handle enables welders to easily reduce airflow by up to 10 cfm to help overcome porosity issues. · Upgraded handle comfort: Two handle styles are available to suit different grip styles and hand sizes, with internals contoured to enhance airflow and fume capture. The lever trigger can also be mounted on top for additional comfort. · Increased flexibility: A durable, lightweight aluminum ball swivel at the end of the handle provides 15 degrees of extra flex in any direction for additional improved ergonomics. · Maximized airflow: A new Y-connector offers contoured internals that maximize airflow, with a vacuum outlet that is compatible with any fume extraction unit. For a premium fume extraction pairing, operators have the option to connect the Clean Air E™ to the Miller® FILTAIR® 215. Learn more about how the Clean Air E™ can deliver safety, performance and comfort for welders at https://www.startsatthesource.com/ About Bernard Bernard, a leading manufacturer of premium semi-automatic MIG welding guns and consumables, is dedicated to enhancing welding productivity and performance. Headquartered in Beecher, Illinois, Bernard is known for innovative solutions that prioritize operator comfort, ease of maintenance, and exceptional durability. Bernard is a proud brand of Illinois Tool Works Inc. (NYSE: ITW). For more information, visit BernardTregaskiss.com, call 1-855-MIGWELD (1-855-644-9353), email CS@itwmig.com. Contact: Lauren Smith, Hiebing for Bernard/Tregaskiss phone: +1 6082684408 lsmith@hiebing.com The Occupational Safety and Health Administration (OSHA) and other safety regulatory bodies set the allowable exposure limits for weld fumes and other particulates, including hexavalent chromium, with the aim of protecting employees against potential health hazards in the workplace. Providing welding operators with proper ventilation during the welding process is an important step companies can take to help meet the standards — and to help provide a safe and comfortable work environment. Companies may opt to invest in centralized fume extraction systems, which are designed to protect the entire shop area. These systems involve the installation of new ductwork and fans to remove fumes and are highly effective, but they are also more expensive than other options. A viable alternative for some companies is a fume extraction gun used in conjunction with a fume extraction device or localized filtration system. Fume extraction guns are available in a variety of amperages (typically 300 to 600), cable styles and handle designs. As with any welding equipment, they have their best applications, advantages and limitations, as well as recommended techniques for achieving the best results. Fume extraction guns operate by capturing the fume generated by the welding process right at the source, over and around the weld pool. The weld fumes removed by these guns are composed of a combination of the filler metal and base material. Various manufacturers have proprietary means of constructing guns to conduct this action, but at a basic level they all operate similarly: by mass flow, or the movement of material. A vacuum chamber suctions the fumes through the handle of the gun, into the gun’s hose and through to a port on the filtration system (sometimes informally referred to as a vacuum box). Typically, fume extraction guns are larger than regular welding guns, and include the vacuum and hose that are necessary to extract the fumes. Some manufacturers offer fume extraction guns with a vacuum hose swivel on the rear of the handle to make them easier to maneuver. Also, design advancements have minimized the handle weight and size to make the guns as light as possible for operator comfort, while still offering consistent fume extraction benefits. The Bernard® Clean Air E™ fume extraction gun is designed to efficiently capture welding fumes at the source, helping to create a cleaner work environment. This gun is particularly well-suited for applications using solid welding wire and for operations in confined spaces, where fume extraction directly in the welding operator’s breathing zone is essential. Industries that frequently benefit from this technology include shipbuilding, heavy equipment manufacturing, and general fabrication, especially when working with mild or carbon steel. Additionally, for applications in petrochemical industries or those involving stainless steel welding, where higher levels of hexavalent chromium are present, the Clean Air E™ gun provides an effective solution for improving air quality. Designed for high-amperage and high-deposition rate applications, this gun performs best in flat and horizontal welding positions, where it can effectively capture rising fume particles. While fume extraction in out-of-position welding can be more challenging due to the natural rise of fumes, proper technique and positioning can help maximize effectiveness. The Clean Air E™ fume extraction gun operates similarly to a standard MIG gun, making it easy for welding operators to adapt to. To achieve the best results, consider these best practices: By integrating the Bernard® Clean Air™ E fume extraction gun into your welding operations, you can enhance fume control while maintaining welding quality and efficiency. Fume extraction guns operate by capturing the fume generated by the welding process right at the source, over and around the weld pool. As with any piece of welding equipment, fume extraction guns benefit from preventive maintenance. Flux-cored wire allows vacuum adjustment Because flux-cored wire produces a slag, it generates more weld fume. However, one benefit of using self-shielded flux-cored wire, for example, is it allows the ability to increase the vacuum level of the gun. Welding operators can close off all the vents and utilize the long shroud. This action maximizes the vacuum at the front end of the gun without concern for disturbing the shielding gas, since there is none generates with self-shielded flux-cored wire. When using gas-shielded flux-cored wire, a 0 to 15-degree angle will help maximize fume collection. Pause at the end At the end of the weld, welding operators can pause for 10 to 15 seconds, holding the fume extraction gun in place without depositing weld metal. This action allows the gun to capture residual fumes as the weld bead is cooling. Wire type determines stickout The contact tip to work distance can be longer — about 1/2 inch to 3/4 inch — when welding with flux-cored wire and a fume extraction gun. With solid wire, welding operators should try to keep the stickout to 1/2 inch or less to maximize fume capture. These lengths are comparable to the stickout lengths used with standard MIG guns. Experiment with the air control regulator Some guns, like the Clean Air E™, incorporate a slider or toggle mechanism conveniently located on the gun handle, while others integrate this function internally. This adjustability is essential for balancing fume extraction with shielding gas coverage. Too much suction can disrupt the protective gas flow, leading to weld defects like porosity, while too little may not effectively capture harmful fumes. By using the built-in adjustment feature, operators can increase or decrease suction as needed to maintain optimal fume control while ensuring proper weld protection. Finding the right balance may require some trial and error. To optimize performance, welding operators should test the air control setting on scrap material before welding on a final product. This ensures that fume extraction is maximized without negatively affecting weld quality. With the Clean Air E™ and other adjustable fume extraction guns, operators have greater control over their work environment—helping to improve air quality while maintaining welding efficiency. As with any piece of welding equipment, fume extraction guns benefit from preventive maintenance. Caring for them is similar to caring for a standard MIG gun. Also note that using flux-cored wire with these guns requires more frequent gun maintenance than solid wire because of the slag and fumes it generates. Regular maintenance is important to help prevent a clog or spatter buildup, which can limit the fume capture rate. Inspecting and maintaining the front end of the gun is key to optimizing fume extraction. Frequently inspect the nozzle and contact tip for signs of spatter buildup, which along with blocking the fume extraction can also obstruct shielding gas flow and cause weld defects. Spatter buildup also can cause consumables to fail prematurely. Replace the consumables if spatter buildup appears, or clean them according to the manufacturer’s recommendations. Also, inspect the vacuum hose regularly for damage such as cuts or kinks, which can lead to loss of suction. Replace a damaged vacuum hose as necessary. Regarding consumables, using the manufacturer’s recommended consumables package with a fume extraction gun helps optimize performance, as the guns are engineered to get the best results with specific consumables. When in doubt about maintenance or any other aspect of using a fume extraction gun, consider working with a trusted welding distributor, certified industrial hygienist and/or the gun manufacturer to address any questions or concerns. In combination with many other variables in the welding operation — wire selection, specific transfer methods and welding processes, welding operator technique, and base material selection — fume extraction guns can help companies maintain compliance with safety regulations and create a cleaner, more comfortable welding environment. Proper use and maintenance of the equipment is important to get optimal results.

New industry standards from the Occupational Safety and Health Administration (OSHA) are protecting employees against potential health hazards in the workplace. These regulations, which dictate allowable exposure limits of welding fumes and other particulates (including hexavalent chromium), have led many companies to invest in fume extraction equipment. An increased desire to maintain optimal welding operator safety and to attract new skilled welding operators to the field is also a consideration in investing in this equipment — companies want to create the most comfortable and healthy work environment possible. The Clean Air E™ MIG fume extraction gun, as shown here, operates by capturing the fume generated by the welding process right at the source, over and around the weld pool. With interchangeable shroud options to help customize your extraction for your application. Some companies may opt for centralized fume extraction systems, which are designed to protect the entire shop area. These systems involve the installation of new ductwork and can be a costly investment for capturing fume particulate in the air. Fume extraction guns are available in a variety of amperages, cable styles and handle designs. As with any welding equipment, they have their advantages and limitations, best applications, maintenance requirements and more. In combination with many other variables in the welding operation; welding wire selection, specific transfer methods and welding processes, welding operator behavior and base material selection — fume extraction guns can help companies maintain compliance with safety regulations and create a cleaner, more comfortable welding environment. Fume extraction guns operate by capturing the fume generated by the welding process right at the source, over and around the weld pool. Various manufacturers have proprietary means of constructing guns to conduct this action, but at a basic level they all operate similarly: by mass flow, or the movement of material. This movement occurs by way of a vacuum chamber that suctions the fumes through the handle of the gun, into the gun’s hose through to a port on the filtration system (sometimes informally referred to as a vacuum box) like the Miller FILTAIR® 215 High-Vacuum Fume Extractor. The welding fumes that these guns remove are composed of a combination of the filler metal and base material. Some fume extraction guns feature adjustable extraction control regulators at the front of the gun handle, which allow welding operators to increase suction as needed (without affecting shielding gas coverage), while others provide this function internally. Regardless of the manner, the ability to balance between the downward flow of shielding gas and the upward flow of the suctioned air is critical. The fume extraction gun needs to provide the appropriate amount of shielding gas to protect the weld from defects such as porosity, without sacrificing the ability to suction fumes efficiently enough to protect the welding operator. The balance allows the weld pool time to react and solidify, and gives the fume particles time to decelerate so they are easier to extract. Typically, fume extraction guns are larger than regular welding guns and tend to be bulky due to the vacuum and hose necessary to extract the fumes. For that reason, some manufacturers create fume extraction guns with a vacuum hose swivel on the rear of the handle to make them easier to maneuver. Manufacturers have also, since fume extraction guns were first introduced (in the late 1960s and early 1970s), found ways to engineer internal components to minimize the handle weight in order to reduce operator fatigue. Fume extraction guns are well-suited for applications using solid welding wire and those in confined spaces. These include, but are not limited to applications in the shipbuilding and heavy equipment manufacturing industries, as well as general manufacturing and fabrication. They are also ideal for welding on stainless steel applications, as this material generates greater levels of hexavalent chromium, and on mild and carbon steel applications. The guns also work well on high amperage and high deposition rate applications and are available, typically, in 300 to 600 amp ranges. Fume extraction guns attach to a localized filtration system, as shown here. Fume removal occurs by way of a vacuum chamber in the fume extraction gun that suctions the fumes through the handle of the gun, into the gun’s hose through to a port on the filtration system. For the best results, fume extraction guns should be used for in-position welding, such as on flat butt welds. In this position, they can most effectively capture fume particles as they rise from the weld pool. In out-of-position welds, the energy of the fume particles causes them to rise at a high rate, making it more difficult for the fume extraction gun to draw them downward and through the vacuum hose. One distinct advantage to fume extraction guns is that they remove the fumes at the source. This will minimize the amount that enters the welding operator’s immediate breathing zone. As with any piece of welding equipment, fume extraction guns benefit from preventive maintenance. Caring for them is similar to caring for a standard GMAW gun. Regularly check for tight connections throughout the length of the fume extraction gun to ensure good electrical flow. Minimizing electrical resistance helps ensure consistent weld quality and prevent premature failure of the front-end consumables — contact tip, nozzle and diffuser. Frequently inspect the nozzle and contact tip for signs of spatter build-up, too, as such build-up can obstruct shielding gas flow and cause weld defects that ultimately will need to be reworked. Spatter build-up can also cause consumables to fail prematurely. Replace the consumables if spatter build-up appears or clean them according to the manufacturer’s recommendation. In some cases the shroud that surrounds the nozzle may also have to be replaced or cleaned free of spatter. To ensure optimal fume extraction capabilities, inspect the vacuum hose regularly for damage, including cuts or kinks that could lead to loss of suction. Replace a damaged vacuum hose as necessary and dispose of it according to the manufacturer’s and/or an industrial hygienist’s directions. Visually inspect the handle for cracks or missing screws, and also check that the gun’s trigger is not sticking or otherwise malfunctioning. Replace or repair these components as necessary. Finally, maintenance on the liner is also important. As with the vacuum hose, use compressed air to clear out any potential blockages during welding wire changeovers or when removing the wire from the gun. Spending an extra few minutes clearing out any debris from the liner can save considerably more time than troubleshooting the weld defects and equipment problems that can result from blockages. Also, track the amount of time that it takes for a liner to wear during the course of the welding operation. Replace the liner prior to that in the future to prevent downtime for replacement during shifts or problems with wire feeding or quality. When in doubt about maintenance or any other aspect of using a fume extraction gun, consider working with a trusted welding distributor, certified industrial hygienist and/or the fume extraction gun manufacturer to address any questions or concerns. Proper use of this equipment can help provide optimal results, and improve the safety and comfort of the welding environment. Regardless of your experience level, keeping your weld environment safe is a top priority. A multifaceted approach to fume mitigation can help you maximize safety and efficiency. Could it be time to take a closer look at your fume control strategies? Read our article published in the February issue of Fabricating & Metalworking. For the past 40 years, 4-Star Trailers in Oklahoma has built high-quality aluminum stock and horse trailers. Aluminum is lightweight, corrosion-resistant, and strong—ideal for trailers designed to endure tough road conditions. However, welding aluminum with a push-pull gun has its challenges. The heaviness of the tool can make it difficult to maneuver in tight angles, and the added weight can lead to welder fatigue, especially when working on large parts or frames. Additionally, this setup can cause delays in production timelines due to discomfort and inefficiency during long hours of use. Before switching to the Bernard® BTB Semi-Automatic Air-Cooled MIG Gun, the team regularly faced feeding issues. The feeding problems were especially noticeable when working on large aluminum parts, causing disruptions and affecting their ability to keep up with demanding production schedules. The difficulty in maneuvering the push-pull gun, coupled with the physical strain it placed on welders, contributed to frequent delays and a slower pace of work. The BTB Gun has been a game-changer. It pushes aluminum wire long distances with ease, something that wasn’t possible with the previous system. Its design is lightweight and maneuverable, making it far easier for welders to handle, especially in tight spots. This has significantly reduced fatigue, allowing the team to work longer and more comfortably without sacrificing quality. The customizable neck lengths of the BTB Gun are another huge advantage, allowing welders to reach into tight angles or handle bigger components with greater ease. The Easy Feed Liner in the BTB Gun reduces friction, making it simpler to feed aluminum wire and minimizing downtime—critical for maintaining a steady workflow in a busy shop. With fewer interruptions, the team is able to stick to production goals and meet deadlines more effectively. The use of AccuLock consumables also contributes to less maintenance, as they last longer than other options, cutting down on the frequency of replacements and the time spent on maintenance tasks. The biggest benefit? The team is more productive and satisfied with their work. With fewer interruptions and smoother operations, they’re able to produce high-quality welds faster. The BTB Gun has not only made their jobs easier but also helped the business run more efficiently. It’s become an indispensable tool in their shop, enabling them to build even tougher, more dependable trailers while improving overall productivity and welder satisfaction. MIG welding is a common welding process especially useful for beginner and DIY welders due to its easy-to-learn nature, shorter lead times and lower production costs. The versatility of MIG welding allows users to work on a wide range of materials with less stopping and restarting. The process features a continuous consumable wire electrode being fed through a welding gun and into a weld pool. The gun also feeds a shielding gas alongside the wire to protect the weld pool from contaminants. While there are different types of MIG guns that have unique parts (e.g., water-cooled, air-cooled, fume extraction), all MIG guns have some parts in common. Understanding the components of a MIG gun and the process by which it works will help you make decisions on the consumables and gun type you select for your job. Here’s what you need to know. 1. Nozzle 2. Contact Tip 3. Diffuser 4. Liner 5. Neck 6. Handle and Trigger 7. Cable Assembly 8. Insulator 9. Power Pin We’re thrilled to announce that Bernard® and Tregaskiss® have undergone an exciting brand refresh. As of today, you will notice our updated logos and visual branding on our website, social media channels, and promotional items. This change marks a significant step forward in our journey to enhance our brands’ presence and commitment to excellence in the welding industry. In a competitive market, it’s essential to evolve and stay ahead. Our refreshed visual identity reflects our We’re confident that these updates will strengthen our brands and provide you with an even better Mastering preventive maintenance, timely consumable replacements, and proper liner trimming are key to prolonging the lifetime of MIG welding equipment. Discover proactive measures to follow for enhancing durability and performance while decreasing downtime, boosting productivity, and cutting operating costs by reading our full article in the March 2024 issue of MetalForming Magazine. MIG welding is considered one of the easiest welding processes to learn and is useful for a variety of applications and industries. To maximize the benefits this versatile process offers, it is imperative to select the right MIG gun for the job. Choosing the right MIG gun directly affects efficiency, quality and safety — a trifecta every operator is trying to master to create a more comfortable and effective environment. There are five key factors when choosing the right MIG gun for your needs. More and more welding operations are investing in robotic welding systems to gain a competitive edge. Such systems not only deliver fine-tuned programming to ensure the accuracy, speed and repeatability needed for generating high-quality welds, they also further productivity and efficiency for an operation. Along with the productivity gains and quality improvements, saving money is a key reason companies are choosing to implement them. Here are seven ways companies can increase cost savings and ROI — beyond the benefits of the robotic welding system itself. Regardless of your skill level, you need to make sure that the equipment you use, works as hard as you do. Consider these components of your welding system to help weld conistency. Could it be time to take a good look at your equipment? Read our article published in the November issue of Fabricating & Metalworking.The New Clean Air E™ Fume Extraction MIG Gun Offers Superior Fume Capture, Enhanced Ergonomics

The New Clean Air E™ Fume Extraction MIG Gun Offers Superior Fume Capture, Enhanced Ergonomics

Up to 95% fume capture efficiency and optimized design make workspaces safer and reduce welder strain

Attacking Weld Fume at the Source

Attacking Weld Fume at the Source

The basics

Benefits of the Bernard® Clean Air™ E Fume Extraction Gun

Maximizing Performance

Proper maintenance and consumable usage

Fume extraction guns can provide results

Learn more about the Bernard® Clean Air E™

Fume Extraction Guns: Understanding the Basics

Fume Extraction Guns: Understanding the Basics

The basics of fume extraction guns

Applications, advantages and limitations

Maintenance tips

The Importance of Implementing a Layered Approach to Fume Mitigation

The Importance of Implementing a Layered Approach to Fume Mitigation

Bernard® BTB Gun Transforms Aluminum Welding for 4-Star Trailers

Bernard® BTB Gun Transforms Aluminum Welding for 4-Star Trailers

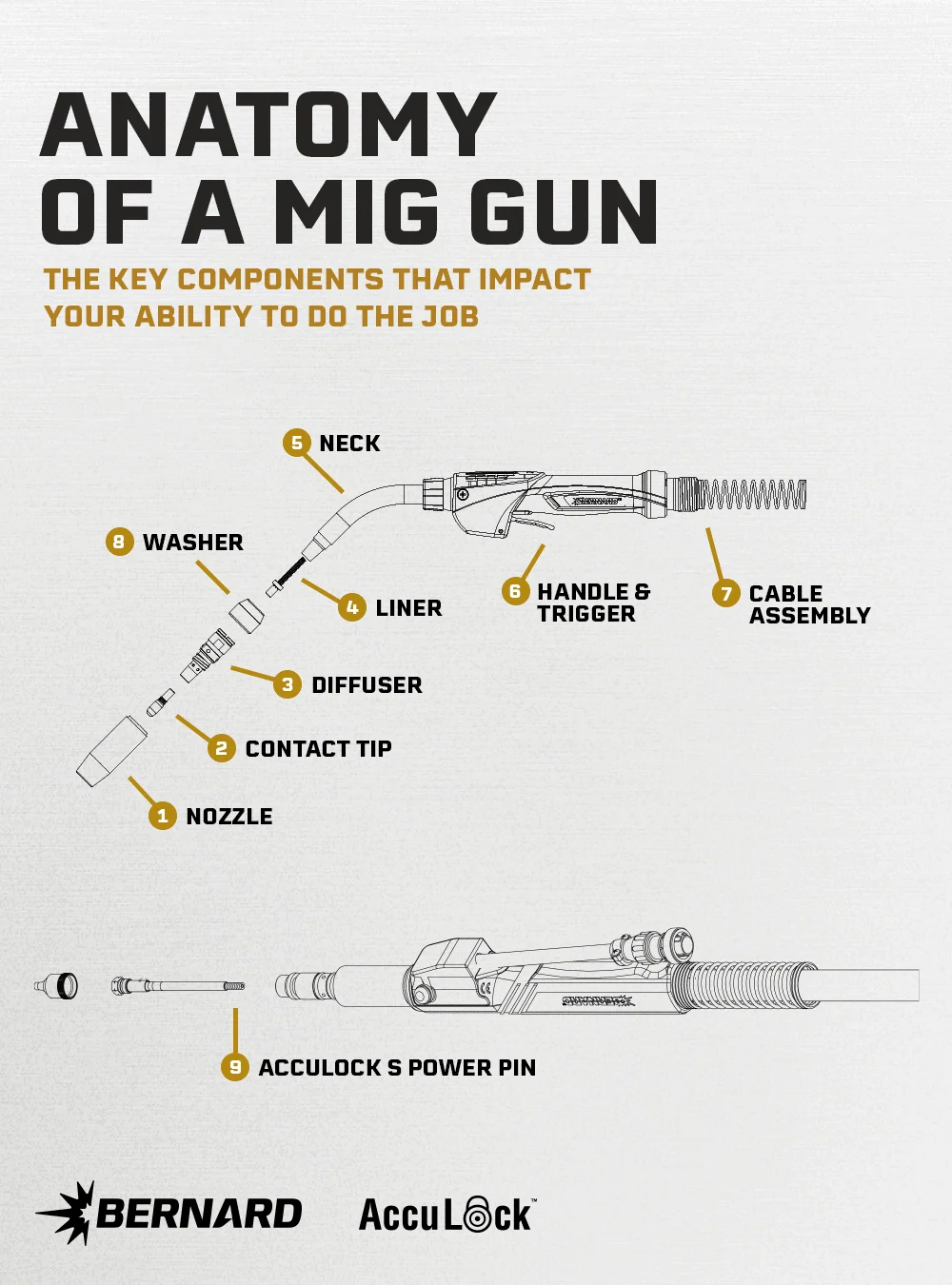

Key MIG Gun Components for Job Performance

Key MIG Gun Components for Job Performance

CONSUMABLES

ESSENTIAL GUN COMPONENTS

OTHER COMPONENTS

A Fresh Look for Bernard® and Tregaskiss®

A Fresh Look for Bernard® and Tregaskiss®

What’s New?

Bernard and Tregaskiss, while maintaining the core values and heritage of our brands.

convenience, tregaskiss.com will continue to redirect to the new site.

millerweldsstore.com and we’ve begun to provide new marketing collateral to our sales team.

rolled out gradually as existing stock is replenished.What’s Staying the Same?

MIG welding solutions remains steadfast.

durability of Bernard and Tregaskiss products.

excellence in robotic MIG guns continue to be the foundation of our brands.Why the Change?

dedication to innovation and leadership in the welding industry. By creating a more cohesive and modern brand image, we are reinforcing Bernard’s reputation as a leader in semi-automatic MIG gun solutions and Tregaskiss’ prominence in robotic MIG guns.Impact on Products and Marketing Materials:

existing stock is replenished.

durability and toughness of our products.

experience. If you have any questions or need further information, please do not hesitate to contact us.Extending the Life of Welding Guns and Consumables

Extending the Life of Welding Guns and Consumables

5 Factors to Consider When Choosing a MIG Welding Gun

5 Factors to Consider When Choosing a MIG Welding Gun

Click here to read the full article featured in the March 2024 issue of Fabricating and Metalworking Magazine.Ways to Save More Money With a Robotic Welding System

Ways to Save More Money With a Robotic Welding System

Read the full article featured in Fabricating & Metalworking Magazine.Five Equipment Adjustments to Improve Weld Quality

Five Equipment Adjustments to Improve Weld Quality