PRODUCT IMPROVEMENT –

Nozzle Detection Option for TOUGH GUN TT3 and TT3E Reamer Robotic Nozzle Cleaning Stations

April 28, 2017

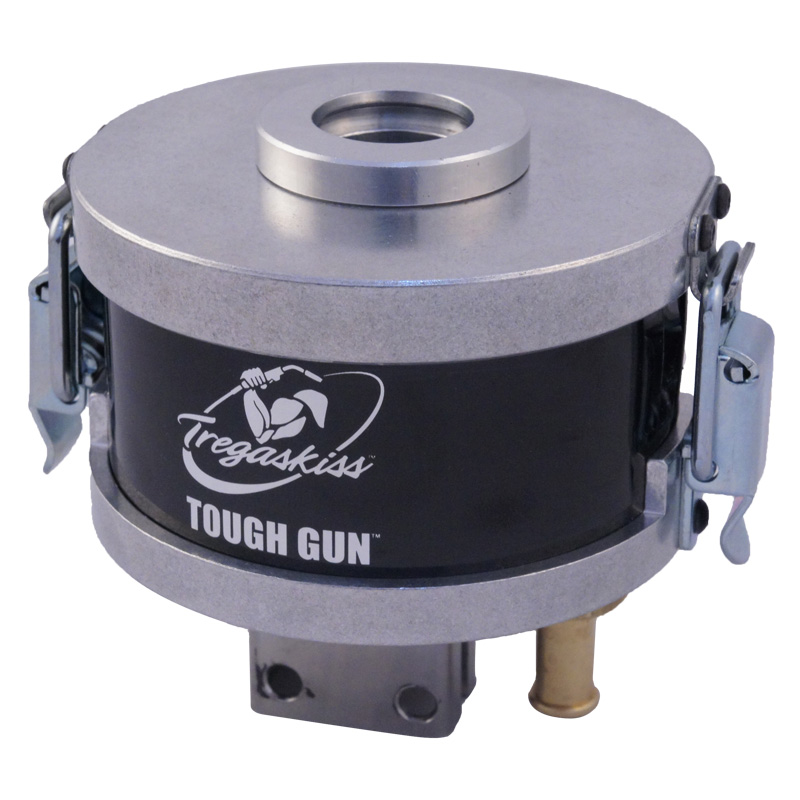

An improvement has been made to the nozzle detect option for our TOUGH GUN® TT3 reamer. This same option is also now available on our TOUGH GUN TT3E reamer.

This new nozzle detect uses a proximity sensor mounted on the side of the reamer that can be used independently of the ream cycle and is compatible with any nozzle size. The robot positions the front end of the MIG gun close to the sensor to detect the presence of the nozzle. If the nozzle is present, a signal is then sent back to the robot controller or PLC.

Affected Part Numbers

- TT-2333 + TT-2334 – OLD nozzle detect for TOUGH GUN TT3 reamer (analog model); available only for 1.062″ nozzle O.D.

- TT3E-2344 – NEW nozzle detect for TOUGH GUN TT3 and TT3E reamer; available for all nozzle O.D. sizes

- RS-500-5 – 4m cable with 3 poles (M12 connector); required for analog model only and only when selecting Nozzle Detection option

- TT3E-2343 – Splitter; required for Ethernet model only and only when selecting both the nozzle detect and the wire cutter options together

To learn more about our TOUGH GUN TT3 reamer offering, or configure your reamer online.

April 28, 2017 Upgrades have been made to the TOUGH GUN® TT3 reamer to allow for a more common design between this model and the TOUGH GUN TT3E reamer. These upgrades include a common frame, replacement of the terminal strip with a new wiring harness, easy access setup switches, and a new check valve. The wiring harness: Click here for additional information about the TOUGH GUN TT3 reamer.

April 15, 2017 The check valve on the TOUGH GUN® TT3 and TT3E reamer robotic nozzle cleaning stations have been upgraded to a more robust and durable design. The new check valve is now common between both the analog and the Ethernet model. Important Notes: Learn more about our TOUGH GUN TT3 reamer offering.

March 16, 2017 Bernard is pleased to announce that we have added a 300 amp model to our Clean Air™ fume extraction MIG gun offering. Reduce smoke at the source with an industrial-duty fume extraction gun that is comparable in size and weight to a regular welding gun. Click here to learn more about the Clean Air fume extraction MIG gun.

February 13, 2017 Tregaskiss is pleased to announce an improvement to our low-stress robotic (LSR) unicable design whereby the cable conduit will be fixed only on the torch end, and floating on the power pin end. This design change will result in a more flexible, less restricted, longer lasting LSR unicable for all TOUGH GUN® TA3 robotic MIG gun product. Click here for more information about low-stress robotic (LSR) unicables.

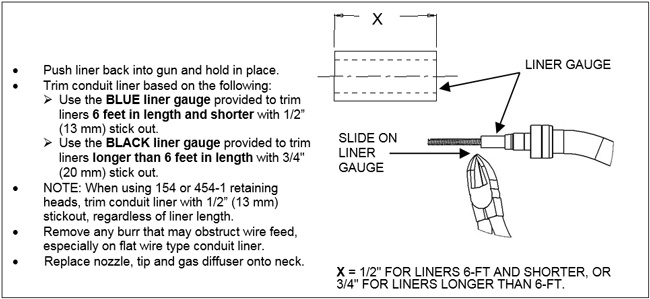

February 3, 2017 Tregaskiss now recommends trimming all rear-loading conventional and front-loading QUICK LOAD® liners that are 6-feet in length and shorter with a 1/2-inch stick out. This new trim length provides performance improvements for the liner and cable, and for wire feeding overall. It also helps to reduce some strain on both the liner and the cable while still maintaining a proper liner seat in both the retaining head and the power pin. Effective late February, all bagged 6-foot Tregaskiss conventional and QUICK LOAD liners will include a new 1/2-inch blue liner gauge along with a technical insert outlining these updated trimming instructions. The outside of each bag will also be marked with a sticker indicating a change to liner trim length.

December 16, 2016 Bernard has changed the finish on all Clean Air™ fume extraction gun vacuum tubes and chambers from chrome to black. Effective immediately, all new guns, replacement vacuum tubes and replacement chambers will have the new darker finish. This change is purely aesthetic, and has no impact on performance, part numbering or price. Click here for more information about the Clean Air™ fume extraction gun.

December 18, 2019 Tregaskiss manufactures TOUGH GUN® TA3 through-arm welding torches for many Yaskawa® Motoman® robot models including but not limited to: On the current robot models listed above, the spacers and through-arm cables on a Tregaskiss® gun may originate from either Tregaskiss or from Yaskawa Motoman. It is important to note that the spacers and cables from Tregaskiss have significantly different dimensions than these same items from Yaskawa Motoman. This means that they are NOT interchangeable. Ordering the wrong replacement spacer and/or cable for an existing installation will significantly impact Tool Center Point (TCP) and cable life – please see Configuration Comparison Chart below for both solid mount and clutch mount setups with a short 45-degree neck for reference. For each model above, when a TOUGH GUN TA3 MIG gun is configured through Tregaskiss, the complete torch solution is Tregaskiss branded and includes: consumables, neck, torch, cable and power pin. For AR/MA1440, MH12, AR/MA2010, AR/MA3120, AR1730, MH24 models, the system also includes a Tregaskiss-specific aluminum spacer which allows us to bury the cable termination into the torch and away from the articulation on axis 5. When Yaskawa Motoman integrates a welding solution with Tregaskiss product, a Motoman through-arm cable replaces the Tregaskiss through-arm cable for all models listed above (consumables, neck, torch and power pin remain Tregaskiss branded). For AR/MA1440, MH12, AR/MA2010, AR/MA3120, AR1730, MH24 models, the system also includes a Motoman-specific plastic torch spacer which allows us to bury the cable termination into the torch and away from the articulation on axis 5. This Motoman spacer is shorter than the Tregaskiss spacer and as a result, the Motoman cable for this setup is also shorter than the Tregaskiss-specific setup. NOTE: Reference chart above is applicable for Yaskawa Motoman robot models AR/MA1440, MH12, AR/MA2010, AR/MA3120, AR1730, MH24. 58SM016 Solid Mount Solid Mount Motoman Solid Mount 58SM002 58SM038 58SM038AW MA3120, AR3120 Solid Mount AS-114-13 58SM032 58SM032A 58SM032W 58SM032AW 58SM039 58SM039W Clutch 58CM016A 58CM016AW Motoman EA1900 XRC Clutch N/A 58CM001A Motoman 58CM035 Motoman 58CM002AW AS-114-13 Clutch 58CM031W 58CM031AW Clutch 58CM032 58CM032A 58CM032W 58CM039W NOTE: If Tregaskiss® TOUGH GUN I.C.E.® technology is required for your application, the cable must be purchased from Yaskawa Motoman for all of their robot models. If you require Yaskawa Motoman components, please contact Yaskawa Motoman directly. Otherwise, if you require Tregaskiss components, please contact us for assistance.

The new C series straight handle expands our handle offering from six to seven options within our Bernard BTB MIG gun configurator. This new handle provides all the same benefits as our current T series straight handle, plus additional enhancements such as comfortable handle overmolding and an ergonomic rear swivel. Click here to learn more about the new C series straight handle.

June 27, 2016 The TOUGH GARD® spatter cleaner was discontinued on December 31, 2014. Some replacement parts for this discontinued product continue to be available. Prices and availability of these replacement parts are subject to change without notice.

June 8, 2016 Tregaskiss is pleased to announce that the TOUGH GUN® TA3 robotic air-cooled MIG gun offering has now been expanded to include configurations for the Panasonic® TM-2000 robot model. Click here to learn more about the TOUGH GUN TA3 robotic air-cooled MIG gun.

June 6, 2016 Effective immediately, the PER-2510 air motor for the discontinued TOUGH GARD® spatter cleaner is no longer available through Tregaskiss. As a result, the PER-2599 kit will no longer include the PER-2510 air motor (please see revised PER-2599 kit parts breakdown below). This Fiam® air motor may be available directly through another vendor (list provided below): Access a complete list of available and discontinued replacement parts for the TOUGH GARD spatter cleaner here.

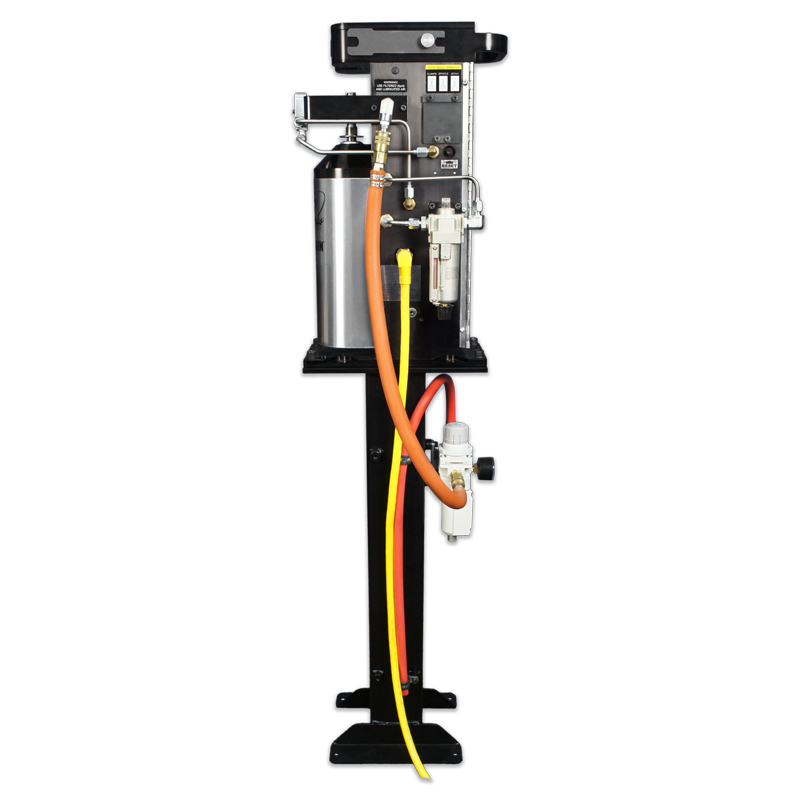

Tregaskiss proudly announces its new TOUGH GUN® reamer stand. This simple fixed height durable stand is compatible with all TOUGH GUN TT3 and TT3E reamer models and can be ordered to a custom height between 18 and 45 inches. This new simplified design also allows for quick installation and new lower pricing. Click here to learn more.

March 26, 2016 Tregaskiss is pleased to announce the new TOUGH GUN® TT3E reamer robotic nozzle cleaning station offering the same high levels of durability, serviceability and repeatability now further enhanced by digital Ethernet communications that better integrate this unit into the digital controls infrastructure of your facility. Enjoy greater control optimization, remote monitoring capability, and faster troubleshooting of all discrete TOUGH GUN reamer I/O functions to facilitate increased productivity in your robotic welding applications. Automating spatter removal will help to extend the life of your robotic MIG guns and consumables, benefiting both your bottom line and production uptime and throughput.

November 23, 2015 Bernard has redesigned the trigger control plug housing on located on the rear strain relief as well as the trigger control plug connection on BTB MIG guns. This change provides an internal connection which is more durable and also allows the strain relief to fit more easily into various feeders from major manufacturers. The double-life MIG gun system also known as the “flip-flop” for T series straight handles is still compatible with this change. Did any part numbers change? Answer: Yes, part numbers have changed. Please reference the charts below for new part numbers for the trigger control plug housing and trigger control plugs. Please see the chart below for trigger control part numbers based on the gun model. Example: Q2015AB8CMC How can you tell the difference between the old version and the new 2015 design?

July 8, 2015 Tregaskiss is pleased to announce that the TOUGH GUN® TA3 robotic air-cooled MIG gun offering has been expanded to include configurations for FANUC® M710iC-12L and Kawasaki® BA006N robot models. Click here to learn more about the TOUGH GUN TA3 robotic air-cooled MIG gun.

January 16, 2015 Tregaskiss has improved the crimp on our heavy duty (HD) nozzle offering. The profile on the crimping dies that form the ring crimp has been narrowed from a pad length of 0.450″ to a pad length of 0.390″ (see image below). This change significantly improves the quality of the crimp since it allows for enhanced integrity of the nozzle insulator. Click here to download the TOUGH LOCK® consumables spec sheet in PDF format for more detailed nozzle information.

Effective April 30, 2015 Miller Electric Mfg. Co. discontinued the Roughneck® C-Series MIG gun series and replaced them with Bernard® BTB semi-automatic air-cooled MIG guns. Miller Electric will continue to offer consumables and replacement parts for the Roughneck C-Series MIG guns. Please see the cross reference chart below to find the replacement Bernard BTB MIG gun part numbers for the Roughneck C-Series MIG guns: Q3010TE5EMC 12 ft (3.7 m) C-3015 Q3015TE5EMC Q4010TE5EMC C-4012 Q4012TE5EMC 194756 194757 S5010GH5IMC 10 ft (3 m) 194758 C-5012 S5015GH5IMC Certain products are only available for purchase from Miller Electric while others are available from either Miller Electric or Bernard. Please see the reference chart below which indicates where you can place an order for the guns, parts and consumables: PRODUCT WHERE TO BUY FasTip™ Consumables Miller Electric Mfg. Co. Quik Tip™ Consumables Miller Electric Mfg. Co. or Bernard Roughneck® Replacement Parts Miller Electric Mfg. Co. Bernard BTB MIG Guns Miller Electric Mfg. Co. or Bernard Bernard BTB MIG Gun Replacement Parts Miller Electric Mfg. Co. or Bernard To place an order through Miller Customer Service: please contact us via phone: 866-931-9730, fax: 800-637-2315 or email orders@millerwelds.com To place an order through Bernard Customer Service: please contact us via phone: 1-855-MIGWELD (644-9353), fax: 888-946-67-26 or email cs@itwmig.com If you are unable to find the answer you are seeking in the following FAQs, please contact the Miller and Bernard Customer Service Teams. 1. Q: Can I use Miller FasTip™ Consumables on the replacement Bernard BTB MIG Guns? A: Although we recommend the use of Bernard Quik Tip™ Consumables, users can install the FasTip diffuser on Bernard Best of the Best BTB MIG Guns and use FasTip Consumables (contact tips, nozzles). Users will need to order a neck insulator part # 4523R for use on Bernard BTB MIG Guns when using FasTip Consumables. Please use the FasTip consumable chart below as a reference: Contact Tip* M206188 M206190 Diffuser M206195 Nozzle M198855 M199618 Insulator 4523R * Based on wire size range 0.045″ – 1/16″ 2. Q: Can I use Miller Roughneck Liners on Bernard BTB MIG Guns? A: No, Users will need to order Bernard Universal Conventional Liners for Bernard BTB MIG Guns. Miller Roughneck Liners are not compatible on Bernard BTB MIG Guns. 3. Q: Can I use Bernard™ Quik Tip™ Consumables on existing Roughneck MIG Guns? A: Yes, the Quik Tip Consumable Series (contact tip, diffuser, nozzle) can be installed on Miller Roughneck MIG Guns. Users will need to order neck insulator part # 10012 to use on their Roughneck MIG Gun when using Bernard Quik Tip Consumables. Please use the consumable chart below as a reference: Contact Tip* T1045 T1116 Diffuser D118Q D114Q Nozzle N1C58Q N1C34HQ Insulator 10012 *Based on wire size range 0.045″ – 1/16″ 4. Q: Can I use Bernard Universal Conventional Liners on existing Roughneck MIG Guns? A: No, Users will still need to order Miller Roughneck Liners for existing Roughneck MIG Guns. Bernard Universal Conventional Liners are not compatible with existing Roughneck MIG Guns. 5. Q: Why does my Miller FasTip diffuser not thread on correctly to a Bernard BTB MIG Gun? A: A change to the thread on the FasTip diffuser was made on February 13, 2015 to be compatible with Bernard BTB MIG Guns. The new style diffuser has a large Miller logo roll mark compared to the old style diffuser that has a small Miller logo rollmark. To differentiate between the old and new style diffusers please see the comparison images below: 6. Q: How does a Miller Roughneck Gun compare to a Bernard BTB MIG Gun? A: Please see full gun comparison images below of the Roughneck C-Series MIG Gun (bottom) and Bernard BTB MIG Gun (top):

June 23, 2015 This innovative spray containment unit from Tregaskiss helps prevent air contamination by catching anti-spatter overspray in its sealed basin, improving the air quality of the working environment and maintaining the cleanliness of the weld cell. Not sure what type of nozzle you have? Download the Tregaskiss nozzles spec sheet in PDF format. Click here to learn more about the spray containment unit.

December 31, 2014 The TOUGH GARD® spatter cleaner has been discontinued as of December 31, 2014. Replacement parts will continue to be available until December 31, 2015. Prices and availability of these replacement parts are subject to change without notice. Consider an upgrade to the TOUGH GUN® TT3 (analog) or TT3E (Ethernet) reamer robotic nozzle cleaning station from Tregaskiss. Click here to learn more. Click here to download the M075 TOUGH GARD spatter cleaner technical guide.

Liners are still available in lengths of up to 25 feet (7.6 m) for various wire sizes. Part numbers will remain the same as released on June 2, 2014. Please see the chart below for part numbers and wire sizes: 0.023″- 0.030″ Yellow L1A-15 L1A-25 0.030″- 0.035″ Green L2A-15 L2A-25 0.035″- 0.045″ White L3A-15* L3A-25* 0.045″- 1/16″ Red L4A-15** L4A-25** 5/64″ Blue L6A-15 L6A-25 3/32″ Grey L7A-15 L7A-25 7/64″ – 1/8″ Black L8A-15 L8A-25 *Standard Liner for 0.035″-0.045″ Guns

Bernard has transitioned these products to a new supplier! Customers can contact Hopkin Manufacturing directly to place orders for these products. Hopkin Manufacturing: +1-800-524-1458 | hopkinsmfg.com

October 31, 2014 Tregaskiss is pleased to bring you the TOUGH GUN® TA3 robotic air-cooled MIG gun. Designed for today’s through-arm style robots, the TOUGH GUN TA3 robotic air-cooled MIG gun combines the most valuable options of our TOUGH GUN ThruArm™ G1 and G2 series platforms – including our low-stress robotic (LSR) unicable – along with new features for increased strength and durability.

Learn more on the Clean Air™ fume extraction gun product page

PRODUCT UPDATE – TOUGH GUN TT3 Reamer Upgrades

PRODUCT UPDATE –

TOUGH GUN TT3 Reamer UpgradesTerminal Strip vs. Wiring Harness

New Easy Access Setup Switches

New Check Valve

PRODUCT IMPROVEMENT – New TOUGH GUN TT3 Reamer Check Valve

PRODUCT IMPROVEMENT –

New TOUGH GUN TT3 Reamer Check Valve

(previously used on the TOUGH GUN TT3 Reamer)

(previously used on the TOUGH GUN TT3E Reamer

(replaces SR-500-20 and OLD TT3E-500-20)PRODUCT UPDATE – 300 amp Clean Air Fume Extraction MIG Gun Now Available

PRODUCT UPDATE –

300 amp Clean Air Fume Extraction MIG Gun Now Available

Features and Benefits

PRODUCT IMPROVEMENT – LSR Unicables

PRODUCT IMPROVEMENT –

Low-Stress Robotic (LSR) Unicables

OLD LSR Unicable Design

NEW LSR Unicable Design

PRODUCT UPDATE – New Liner Trim Length for Liners 6-Feet Long and Shorter

PRODUCT UPDATE –

New Liner Trim Length for Liners 6-Feet Long and Shorter

NOTE: Liners longer than 6-foot in length should still continue to be trimmed with a 3/4-inch stick out. No change to liner gauges or trim instructions for conventional or QUICK LOAD liners longer than 6-feet is recommended.PRODUCT UPDATE – Clean Air Gun Vacuum Tube and Chamber Finish Change

PRODUCT UPDATE –

Clean Air Gun Vacuum Tube and Chamber Finish Changes

PRODUCT UPDATE – TOUGH GUN TA3 Torch Solutions for Yaskawa Motoman Robots

PRODUCT UPDATE —

Tregaskiss TOUGH GUN TA3 Torch Solutions for Yaskawa Motoman RobotsOverview

Details

Configuration Comparison

Configuration Tregaskiss Cable Motoman Cable Tregaskiss Spacer: AS-114-13 Solid mount, with or without wire brake Yes No Clutch mount, with our without wire brake Yes No Motoman Spacer: 168535-1 Solid mount, with or without wire brake No Yes Clutch mount, with or without wire brake No Yes Proper Setup – No impact on TCP or cable life

A complete Tregaskiss setup consists of all Tregaskiss branded components. The torch spacer will be aluminum and approximately 4-3/8″ in length. The cable will have a corrugated hose from front to back.

A hybrid Tregaskiss/Motoman setup consists of a Tregaskiss torch and consumables with a Motoman spacer and cable. The spacer will be approximately 2-3/8″ in length. The cable will have a loose spring from front to back.Improper Setup – Negative impact on TCP and/or cable life

Installing a Tregaskiss cable on a system with a plastic spacer will result in a cable that is too long. Although this cable can be physically installed, this setup will result in premature cable failure.

Installing a Motoman cable on a system with an aluminum spacer will result in a cable that is too short. This cable will not be long enough to plug the power pin into the wire feederTregaskiss Spacer and LSR Unicable Part Number Reference Chart

Robot Make Robot Model Mount Style Tregaskiss Spacer LSR Unicable Part Number No Options Air Blast Wire Brake Air Blast + Wire Brake Motoman® EA1400 XRC Solid Mount N/A 58SM016A 58SM016W 58SM016AW Motoman EA1900 XRC N/A 58SM017 58SM017A 58SM017W 58SM017AW Motoman EA1400N, SSA2000, MA1400, VA1400 Solid Mount N/A 58SM001 58SM001A 58SM001W 58SM001AW Motoman MA1440, AR1440, MH12 AS-114-13 58SM035 58SM035A 58SM035W 58SM035AW EA1900N N/A 58SM002A 58SM002W 58SM002AW Motoman MA2010, AR2010 Solid Mount AS-114-13 58SM038A 58SM038W Motoman MA3100 Solid Mount N/A 58SM031 58SM031A 58SM031W 58SM031AW Motoman Motoman AR1730, MH24 Solid Mount AS-114-13 58SM039A 58SM039AW Motoman EA1400 XRC N/A 58CM016 58CM016W 58CM017 58CM017A 58CM017W 58CM017AW Motoman EA1400N, SSA2000, MA1400, VA1400 Clutch N/A 58CM001 58CM001W 58CM001AW MA1440, AR1440, MH12 Clutch AS-114-13 58CM035A 58CM035W 58CM035AW EA1900N Clutch N/A 58CM002 58CM002A 58CM002W Motoman MA2010, AR2010 Clutch 58CM038 58CM038A 58CM038W 58CM038AW Motoman MA3100 N/A 58CM031 58CM031A Motoman MA3120, AR3120 AS-114-13 58CM032AW Motoman AR1730, MH24 Clutch AS-114-13 58CM039 58CM039A 58CM039AW

IMPORTANT!

NEW PRODUCT – C Series Handle Option for BTB MIG Guns

NEW PRODUCT –

C Series Handle Option for BTB MIG GunsNew C Series Straight Handle

PRODUCT UPDATE – Replacement Parts Availability for the TOUGH GARD Spatter Cleaner

PRODUCT UPDATE —

Replacement Parts Availability for the TOUGH GARD Spatter Cleaner

Discontinued Replacement Parts

Part Number Description PER-2510 Motor

Available Replacement Parts

Part Number Description ER-2241 Control Valve ER-2242 Sprayer Valve ER-2560 Reed Switch ER-2609 Wiring Interface Receptacle ER-2700 Spatter Cleaner Pneumatic ER-500-15 Spray Head PER-220 Valve Assembly PER-2599 Spatter Cleaner Kit (motor not included) PER-2680 Rear Shroud PER-2685 Front Shroud PER-500-15-6 Reservoir Mount

PRODUCT UPDATE – TOUGH GUN TA3 MIG Gun Offering Available for Panasonic TM-2000

PRODUCT UPDATE —

TOUGH GUN TA3 MIG Gun Offering Available for Panasonic TM-2000

Available Resources

DISCONTINUED PRODUCT – PER-2510 Motor

DISCONTINUED PRODUCT — PER-2510 Air Motor for the TOUGH GARD Spatter Cleaner

Fiam® Air Motor Model Number Part Number 28M100D-3/8-24UNF 185609008

Vendors:

Revised PER-2599 Kit Parts Breakdown

Item Part Number Description Qty Length 1 PER-2511 Motor Clamp Detail 1 3 PER-2611 Spatter Shield Plate, Inner 1 4 F1-M6X1-25B M6x1x25mm LG SHCS, Black Oxide 3 5 F2-M4X.7-6B M4x.7x6mm LG SHCS, Black Oxide 4 7 TR-2231 5/16″ x 1/8″ NPT QC 1 8 ER-2700 ER Reamer Pneumatic Kit 1 Not Shown Red Tape Electrical Red Tape, 18mm Wide 4.5″

Click here to download the archived M075 TOUGH GARD spatter cleaner technical guide. NEW PRODUCT – TOUGH GUN Reamer Stand

NEW PRODUCT —

TOUGH GUN Reamer Stand

NEW PRODUCT – TOUGH GUN TT3E Reamer

NEW PRODUCT —

TOUGH GUN TT3E Reamer

PRODUCT IMPROVEMENT – Trigger Control Plug Housing

PRODUCT IMPROVEMENT –

Trigger Control Plug Housing on BTB MIG Guns

Frequently Asked Questions

Trigger Control Plug Housing Description Old Part Number New Part Number Standard – B & O Series Handles 416-5 1810053 Standard – T Series Straight Handle 416-5 1810052 Dual Schedule 416-13 1810054 Power Pin Old Part Number New Part Number B (Bernard®) N/A N/A E (Euro) N/A N/A L (Lincoln®) 419-6 SCL2N M (Miller®) 419-4 Trigger control plug housing includes trigger control plug O (OXO™) 419-7 SCX1N S (Tweco® #4 – Lincoln Lead) 419-6 SCL2N R (Tweco® #4 – Miller Lead) 419-4 Trigger control plug housing includes trigger control plug T (Tweco® #4 – Standard Lead) 419-8 SCT1N U (Tweco® #4 – NAS Plug) 419-7 SCX1N W (Tweco® #5 – Standard Lead) 419-8 SCT1N X (Tweco® #5 – Miller Lead) 419-4 Trigger control plug housing includes trigger control plug

Answer: New 2015 design will have an internal connection. See Figure below:

PRODUCT UPDATE – Expanded TOUGH GUN TA3 MIG Gun Offering

PRODUCT UPDATE —

Expanded TOUGH GUN TA3 MIG Gun Offering

Available Resources

PRODUCT IMPROVEMENT – Changes to Heavy Duty (HD) Nozzle Crimping

PRODUCT IMPROVEMENT –

Heavy Duty (HD) Nozzle Crimping

Affected Part Numbers

DISCONTINUED PRODUCT – Roughneck MIG Guns

DISCONTINUED PRODUCTS –

Miller Roughneck C-Series MIG GunsMiller Stock Number Roughneck Gun Model Number Bernard BTB MIG Gun Replacement Part Number Gun Length 194751 C-3010 10 ft. (3 m) 194752 C-3012 Q3012TE5EMC 194753 15 ft (4.6 m) 194754 C-4010 10 ft. (3 m) 194755 12 ft. (3.7 m) C-4015 Q4015TE5EMC 15 ft (4.6 m) C-5010 S5012GH5IMC 12 ft. (3.7 m) 194759 C-5015 15 ft. (4.6 m) Where To Order

Frequently Asked Questions (FAQs)

FasTip Consumables 300 amp 400 amp 500 amp Quik Tip Consumables 300 amp 400 amp 500 amp

PRODUCT UPDATE – Spray Containment

PRODUCT UPDATE —

Spray Containment

A perfect addition to the TOUGH GUN TT3 Reamer

Spray Containment Part Numbers

TS-1000-01 for use with Tregaskiss® Heavy Duty (HD) Nozzles (excluding 3/4″ bore) TS-1000-02 for use with Tregaskiss Standard Duty (SD) Nozzles TS-1000-03 for use with Tregaskiss Heavy Duty Nozzles with 3/4″ bore TS-1000-04 for use with Tregaskiss Heavy Duty Bottleneck Nozzles TS-1000-05 for use with Tregaskiss Standard Duty Bottleneck Nozzles DISCONTINUED PRODUCT – TOUGH GARD Spatter Cleaner Robotic Nozzle Cleaning Station

DISCONTINUED PRODUCT — TOUGH GARD Spatter Cleaner Robotic Nozzle Cleaning Station

PRODUCT IMPROVEMENT – Bernard Conventional Liners

PRODUCT IMPROVEMENT –

Bernard Conventional Liners

Bernard has implemented a material change to all Bernard conventional liners. All liners were previously produced from high carbon music wire. All liners will now be produced from high carbon music wire with tin zinc plated coating. Wire Size Liner Color 15′ (4.57 m) 25′ (7.62 m)

**Standard Liner for 1/16″ GunsDISCONTINUED PRODUCT – Manual Products

DISCONTINUED PRODUCT –

Manual Products: Cable Connectors, Lugs and SplicersAs of August 4, 2014, the manual product line (cable connectors, lugs and splicers) from Bernard has been discontinued.

NEW PRODUCT – TOUGH GUN TA3 Robotic Air-Cooled MIG Gun

NEW PRODUCT —

TOUGH GUN TA3 Robotic Air-Cooled MIG Gun

NEW PRODUCT – Bernard Clean Air Fume Extraction Gun

NEW PRODUCT –

Bernard Clean Air Fume Extraction GunNew Clean Air™ Fume Extraction Series

Reduce smoke at the source with an industrial-duty fume extraction gun that is comparable in size and weight to a regular welding gun.