Unlock expert tips on robotic and semi-automatic MIG guns, plus top-tier consumables, through our cutting-edge technical articles and real-world case studies. Stay ahead in the game and sign up now to get the latest insights delivered straight to your inbox Amperage e-newsletter.

- How the Bernard® IronPro™ Keeps Trains on Track at CSX Transportation

In Atlanta, Georgia, CSX Transportation keeps 1,848 trains running every day; a demanding job where every minute of downtime matters. Fast, reliable repairs are critical to keeping operations on track. Before switching to the Bernard IronPro, CSX welders faced constant challenges. The intense heat of track repairs was tough on their old welding guns, which […]

In Atlanta, Georgia, CSX Transportation keeps 1,848 trains running every day; a demanding job where every minute of downtime matters. Fast, reliable repairs are critical to keeping operations on track. Before switching to the Bernard IronPro, CSX welders faced constant challenges. The intense heat of track repairs was tough on their old welding guns, which […] - E-Z MIG Liner Guide

Mastering MIG welding liners: Types, challenges and solutions Liners play a critical role in welding gun performance, directly impacting the quality and efficiency of the welding process. A smooth and consistent wire feed is what facilitates a stable arc and the ability to achieve uniformity of the weld. The choice of liner depends on factors […]

Mastering MIG welding liners: Types, challenges and solutions Liners play a critical role in welding gun performance, directly impacting the quality and efficiency of the welding process. A smooth and consistent wire feed is what facilitates a stable arc and the ability to achieve uniformity of the weld. The choice of liner depends on factors […] - Vactor’s Formula for Better Welding

Building vacuum trucks that keep cities running is no small task. For Vactor Manufacturing, a leader in sewer cleaning and vacuum excavation equipment, every weld matters. These trucks face demanding environments, so durability and precision during production are critical.To meet the demands of heavy-duty welding, Vactor relies on Bernard® BTB MIG Guns and AccuLock™ consumables. […]

Building vacuum trucks that keep cities running is no small task. For Vactor Manufacturing, a leader in sewer cleaning and vacuum excavation equipment, every weld matters. These trucks face demanding environments, so durability and precision during production are critical.To meet the demands of heavy-duty welding, Vactor relies on Bernard® BTB MIG Guns and AccuLock™ consumables. […] - Right-the-First-Time Welding

Fixing defects demands careful planning and expert execution Welding repairs often involve higherstakes than original fabrication. Thepressure is greater, the conditionsare more challenging, and the consequences offailure are more severe. Once a critical weld iscompromised, the risks increase significantly:What was critical becomes supercritical, themargin for error narrows, and the cost offailure multiplies. A failure in […]

Fixing defects demands careful planning and expert execution Welding repairs often involve higherstakes than original fabrication. Thepressure is greater, the conditionsare more challenging, and the consequences offailure are more severe. Once a critical weld iscompromised, the risks increase significantly:What was critical becomes supercritical, themargin for error narrows, and the cost offailure multiplies. A failure in […] - Automation for Better Welding

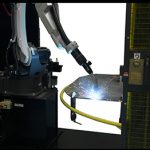

Technology enhancements optimize and advance automated welding performance. The skilled labor shortage is not a new concern within the welding industry. While efforts are being made to attract new talent, those who join still need ample time to learn and truly refine their skills. Because of shortages and the lengthy on-ramps for newer welders, some […]

Technology enhancements optimize and advance automated welding performance. The skilled labor shortage is not a new concern within the welding industry. While efforts are being made to attract new talent, those who join still need ample time to learn and truly refine their skills. Because of shortages and the lengthy on-ramps for newer welders, some […] - Right Equipment, Better Ergonomics

A welder that can keep comfortable doing the job is likely to avoid unnecessary strains It’s no surprise that as welders reach their 30s, they are not as flexible and limber as they were when they were just starting out in the metal fabricating business. What is surprising is that most companies don’t take that into account, […]

A welder that can keep comfortable doing the job is likely to avoid unnecessary strains It’s no surprise that as welders reach their 30s, they are not as flexible and limber as they were when they were just starting out in the metal fabricating business. What is surprising is that most companies don’t take that into account, […] - A Big Win for Clean Air E – Bernard Takes Home a Pro Tool Innovation Award!

Bernard® Clean Air™ E fume extraction gun has been recognized with a 2025 Pro Tool Innovation Award in the Automotive and Metalworking category, under Welding Guns. The Pro Tool Innovation Awards are judged by a panel of contractors, trade professionals, and tool experts who evaluate products based on innovation, performance, and value. These awards highlight […]

Bernard® Clean Air™ E fume extraction gun has been recognized with a 2025 Pro Tool Innovation Award in the Automotive and Metalworking category, under Welding Guns. The Pro Tool Innovation Awards are judged by a panel of contractors, trade professionals, and tool experts who evaluate products based on innovation, performance, and value. These awards highlight […] - Tregaskiss Redefines Performance With New Atlas™ Robotic ThruArm Air-Cooled MIG Torch

Engineered for precision, built for uptime and designed to hit your mark BEECHER, Ill./WINDSOR, Ontario (September 4, 2025) — Tregaskiss, a leading innovator in robotic welding solutions, introduces the Atlas™ robotic MIG welding torch — a next-generation, air-cooled ThruArm GMAW torch engineered to deliver unmatched efficiency, repeatable precision and simplified maintenance. Constructed to endure the demands […]

Engineered for precision, built for uptime and designed to hit your mark BEECHER, Ill./WINDSOR, Ontario (September 4, 2025) — Tregaskiss, a leading innovator in robotic welding solutions, introduces the Atlas™ robotic MIG welding torch — a next-generation, air-cooled ThruArm GMAW torch engineered to deliver unmatched efficiency, repeatable precision and simplified maintenance. Constructed to endure the demands […] - The Hidden Cost of Cutting Corners in Robotic Welding Equipment

The global robotic welding market is heating up. This growth is being fueled by a critical mix of factors: a shortage of skilled welders, the rising demand for manufacturing efficiency, and an industry-wide push toward automation across sectors like automotive, aerospace, construction equipment, and general fabrication. At the center of many robotic welding cells is […]

The global robotic welding market is heating up. This growth is being fueled by a critical mix of factors: a shortage of skilled welders, the rising demand for manufacturing efficiency, and an industry-wide push toward automation across sectors like automotive, aerospace, construction equipment, and general fabrication. At the center of many robotic welding cells is […] - Improved Flux-Cored Welding for Heavy-Duty Field Use

Understanding operator challenges is what drives innovation in the welding industry. For some, that challenge is outdoor welding, where using shielding gas is not optimal. In these extreme conditions, traditional MIG welding won’t necessarily work. Turning to a different process, such as self-shielded flux-cored welding (FCAW-S), allows for more effective welding in the field. When […]

Understanding operator challenges is what drives innovation in the welding industry. For some, that challenge is outdoor welding, where using shielding gas is not optimal. In these extreme conditions, traditional MIG welding won’t necessarily work. Turning to a different process, such as self-shielded flux-cored welding (FCAW-S), allows for more effective welding in the field. When […] - 4 Reasons Genuine Consumables Lead to Better MIG Welds

Welders must be able to rely on every aspect of their equipment, and consumables are an integral component of a high-quality weld. When you notice an uptick in downtime and consumables consumption, it’s time to take a deeper look at what the culprit could be. An easy place to start is by looking at the […]

Welders must be able to rely on every aspect of their equipment, and consumables are an integral component of a high-quality weld. When you notice an uptick in downtime and consumables consumption, it’s time to take a deeper look at what the culprit could be. An easy place to start is by looking at the […] - Mastering MIG welding with adjustments, equipment and techniques

Discover essential adjustments, equipment tips, and expert techniques to accelerate your MIG welding game by reading our article in the October issue of The Welder. You’ll learn how to balance voltage and wire feed speed for flawless welds, select the right welder and shielding gas, and master gun angle and travel speed. Plus, we’ll guide […]

Discover essential adjustments, equipment tips, and expert techniques to accelerate your MIG welding game by reading our article in the October issue of The Welder. You’ll learn how to balance voltage and wire feed speed for flawless welds, select the right welder and shielding gas, and master gun angle and travel speed. Plus, we’ll guide […] - Introducing The Bernard® Clean Air E™

Welding professionals face daily challenges in keeping their work environment clean and safe. With strict weld fume regulations, effective fume control is more important than ever. The Bernard® Clean Air E™ fume extraction MIG gun helps by capturing welding fumes directly at the source without sacrificing performance. Play Why Source Capture Matters Capturing weld fume […]

Welding professionals face daily challenges in keeping their work environment clean and safe. With strict weld fume regulations, effective fume control is more important than ever. The Bernard® Clean Air E™ fume extraction MIG gun helps by capturing welding fumes directly at the source without sacrificing performance. Play Why Source Capture Matters Capturing weld fume […] - The New Clean Air E™ Fume Extraction MIG Gun Offers Superior Fume Capture, Enhanced Ergonomics

The New Clean Air E™ Fume Extraction MIG Gun Offers Superior Fume Capture, Enhanced Ergonomics Up to 95% fume capture efficiency and optimized design make workspaces safer and reduce welder strain

The New Clean Air E™ Fume Extraction MIG Gun Offers Superior Fume Capture, Enhanced Ergonomics Up to 95% fume capture efficiency and optimized design make workspaces safer and reduce welder strain - Attacking Weld Fume at the Source

The Occupational Safety and Health Administration (OSHA) and other safety regulatory bodies set the allowable exposure limits for weld fumes and other particulates, including hexavalent chromium, with the aim of protecting employees against potential health hazards in the workplace. Providing welding operators with proper ventilation during the welding process is an important step companies can […]

The Occupational Safety and Health Administration (OSHA) and other safety regulatory bodies set the allowable exposure limits for weld fumes and other particulates, including hexavalent chromium, with the aim of protecting employees against potential health hazards in the workplace. Providing welding operators with proper ventilation during the welding process is an important step companies can […] - Fume Extraction Guns: Understanding the Basics

New industry standards from the Occupational Safety and Health Administration (OSHA) are protecting employees against potential health hazards in the workplace. These regulations, which dictate allowable exposure limits of welding fumes and other particulates (including hexavalent chromium), have led many companies to invest in fume extraction equipment. An increased desire to maintain optimal welding operator […]

New industry standards from the Occupational Safety and Health Administration (OSHA) are protecting employees against potential health hazards in the workplace. These regulations, which dictate allowable exposure limits of welding fumes and other particulates (including hexavalent chromium), have led many companies to invest in fume extraction equipment. An increased desire to maintain optimal welding operator […] - The Importance of Implementing a Layered Approach to Fume Mitigation

The Importance of Implementing a Layered Approach to Fume Mitigation Regardless of your experience level, keeping your weld environment safe is a top priority. A multifaceted approach to fume mitigation can help you maximize safety and efficiency. Could it be time to take a closer look at your fume control strategies? Read our article published […]

The Importance of Implementing a Layered Approach to Fume Mitigation Regardless of your experience level, keeping your weld environment safe is a top priority. A multifaceted approach to fume mitigation can help you maximize safety and efficiency. Could it be time to take a closer look at your fume control strategies? Read our article published […] - Bernard® BTB Gun Transforms Aluminum Welding for 4-Star Trailers

For the past 40 years, 4-Star Trailers in Oklahoma has built high-quality aluminum stock and horse trailers. Aluminum is lightweight, corrosion-resistant, and strong—ideal for trailers designed to endure tough road conditions. However, welding aluminum with a push-pull gun has its challenges. The heaviness of the tool can make it difficult to maneuver in tight angles, […]

For the past 40 years, 4-Star Trailers in Oklahoma has built high-quality aluminum stock and horse trailers. Aluminum is lightweight, corrosion-resistant, and strong—ideal for trailers designed to endure tough road conditions. However, welding aluminum with a push-pull gun has its challenges. The heaviness of the tool can make it difficult to maneuver in tight angles, […] - Key MIG Gun Components for Job Performance

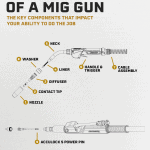

MIG welding is a common welding process especially useful for beginner and DIY welders due to its easy-to-learn nature, shorter lead times and lower production costs. The versatility of MIG welding allows users to work on a wide range of materials with less stopping and restarting. The process features a continuous consumable wire electrode being […]

MIG welding is a common welding process especially useful for beginner and DIY welders due to its easy-to-learn nature, shorter lead times and lower production costs. The versatility of MIG welding allows users to work on a wide range of materials with less stopping and restarting. The process features a continuous consumable wire electrode being […] - A Fresh Look for Bernard® and Tregaskiss®We’re thrilled to announce that Bernard® and Tregaskiss® have undergone an exciting brand refresh. As of today, you will notice our updated logos and visual branding on our website, social media channels, and promotional items. This change marks a significant step forward in our journey to enhance our brands’ presence and commitment to excellence in the welding industry.

- Extending the Life of Welding Guns and ConsumablesExtending the Life of Welding Guns and Consumables Mastering preventive maintenance, timely consumable replacements, and proper liner trimming are key to prolonging the lifetime of MIG welding equipment. Discover proactive measures to follow for enhancing durability and performance while decreasing downtime, boosting productivity, and cutting operating costs by reading our full article in the March […]

- 5 Factors to Consider When Choosing a MIG Welding Gun5 Factors to Consider When Choosing a MIG Welding Gun MIG welding is considered one of the easiest welding processes to learn and is useful for a variety of applications and industries. To maximize the benefits this versatile process offers, it is imperative to select the right MIG gun for the job. Choosing the right MIG gun […]

- Ways to Save More Money With a Robotic Welding SystemWays to Save More Money With a Robotic Welding System More and more welding operations are investing in robotic welding systems to gain a competitive edge. Such systems not only deliver fine-tuned programming to ensure the accuracy, speed and repeatability needed for generating high-quality welds, they also further productivity and efficiency for an operation. Along […]

- Five Equipment Adjustments to Improve Weld QualityFive Equipment Adjustments to Improve Weld Quality Regardless of your skill level, you need to make sure that the equipment you use, works as hard as you do. Consider these components of your welding system to help weld conistency. Could it be time to take a good look at your equipment? Read our article published […]

- Choosing Between Robots and Cobots for Robotic WeldingChoosing Between Robots and Cobots for Robotic Welding Tregaskiss designed its BA1 cobot welding gun to help companies gain the most from their cobot. Learn how to recognize the key nuances between two welding-automation options, robots and cobots and how knowing these differences are essential to attain positive results. Have you ever wondered about the […]

- South Louisiana Community College Chooses Bernard® Semi-Automatic MIG Welding Guns and AccuLock™ Consumables for Welding Education | Customer TestimonialSouth Louisiana Community College (SLCC) has made a game-changing decision to enhance its welding education program by incorporating Bernard semi-automatic welding guns and AccuLock consumables into its classrooms. This shift marks a significant departure from the MIG guns and consumables they had been using for decades. The transition began within the last year after SLCC’s […]

- Understand the Truth About These 7 Robotic Welding Myths

Estimated reading time: 7 minutes Speed, accuracy, repeatability — welding automation boasts some big benefits. Using robots across a myriad of manufacturing applications has been a boon to the welding industry, but it hasn’t come without its fair share of misconceptions. Accepting those misconceptions could actually negate those big benefits — and no one has […]

Estimated reading time: 7 minutes Speed, accuracy, repeatability — welding automation boasts some big benefits. Using robots across a myriad of manufacturing applications has been a boon to the welding industry, but it hasn’t come without its fair share of misconceptions. Accepting those misconceptions could actually negate those big benefits — and no one has […] - Self-Shielded Gun Performance

Estimated reading time: 5 minutes Self-shielded flux-cored welding is frequently used for structural construction and other jobsite welding since it offers a significant productivity advantage compared to stick welding. Welders using this process are likely holding their welding guns for much of the day, and they may be standing on elevated girders or lifts trying […]

Estimated reading time: 5 minutes Self-shielded flux-cored welding is frequently used for structural construction and other jobsite welding since it offers a significant productivity advantage compared to stick welding. Welders using this process are likely holding their welding guns for much of the day, and they may be standing on elevated girders or lifts trying […] - Bernard® and Tregaskiss® offer welding solutions at FABTECH 2023Bernard® and Tregaskiss® offer welding solutions at FABTECH 2023 Tregaskiss and Bernard, manufacturer of semi-automatic, fixed automatic, cobot and robotic MIG welding guns, consumables and peripherals exhibited at FABTECH 2023, September 11-14 in Chicago. FABTECH is North America’s largest metal forming, fabricating, welding and finishing event that brings over 1,500 world-class suppliers worldwide together in […]

- Best Practices For Weld Cell Layout

Today, even the smallest weld shops are making the jump to robotics, and even the largest, highly automated OEMs likely have semiautomatic weld cells for repairs or for welding parts that don’t lend themselves to automation. In automotive manufacturing, these manual cells may be midway through the line for welding frames or at the end […]

Today, even the smallest weld shops are making the jump to robotics, and even the largest, highly automated OEMs likely have semiautomatic weld cells for repairs or for welding parts that don’t lend themselves to automation. In automotive manufacturing, these manual cells may be midway through the line for welding frames or at the end […] - Proper Robotic Welding Gun Configuration

Estimated reading time: 6 minutes The welding gun is a vital piece of equipment in a robotic welding system, serving as the conduit for the welding wire, gas, and power. However, it can sometimes be an afterthought when companies implement an automated welding solution. Unfortunately, this oversight can lead to a host of problems, not […]

Estimated reading time: 6 minutes The welding gun is a vital piece of equipment in a robotic welding system, serving as the conduit for the welding wire, gas, and power. However, it can sometimes be an afterthought when companies implement an automated welding solution. Unfortunately, this oversight can lead to a host of problems, not […] - MIG Welding FAQ: Best Practices for MIG Success

Estimated reading time: 6 minutes MIG is the most frequently used welding process in general manufacturing and fabrication, thanks to its ease of use, versatility, and productivity benefits. While MIG is widely used, some operations may still run into issues that require troubleshooting. Understanding the basics of MIG welding and following best practices for operator […]

Estimated reading time: 6 minutes MIG is the most frequently used welding process in general manufacturing and fabrication, thanks to its ease of use, versatility, and productivity benefits. While MIG is widely used, some operations may still run into issues that require troubleshooting. Understanding the basics of MIG welding and following best practices for operator […] - Upfront Cost vs. Total Cost of Ownership of MIG Guns and ConsumablesEstimated reading time: 4 minutes While it may be tempting for companies to purchase MIG welding guns and welding consumables based on price, lower upfront costs don’t always add up to savings. Less expensive products often lack in quality and bring risk to the profitability of the welding operation. This can come in the form […]

- Employee Training: Best Practices for Preparing New WeldersEstimated reading time: 4 minutes Given the industry statistics regarding the number of experienced welders who are retiring from the field, many companies are likely training more new welders than ever before. By 2023, the nation’s workforce will need over 375,000 welders to satisfy the demands of several industries. [1] Welding is obviously a hands-on skill, […]

- Making a MIG Gun Last in Harsh Manufacturing EnvironmentsWhether it’s a high amperage application, high or low ambient temperatures, or humidity, harsh manufacturing environments can be tough on welding equipment — including MIG guns and consumables. Confined, cluttered or dirty weld cells can also negatively affect this equipment. Whether it’s a high amperage application, high or low ambient temperatures, or humidity, harsh manufacturing […]

- Using Root Cause Analysis to Address Welding Consumable IssuesEstimated reading time: 4 minutes Troubleshooting problems with welding consumables can be time-consuming and expensive. From the associated downtime to the cost of replacing contact tips, diffusers, nozzles and liners, companies stand to lose productivity and potentially miss production goals. Applying root cause tools can help expedite the process of consumable troubleshooting. These are structured […]

- Welder Training Tips to Help Improve ProductivityEstimated reading time: 6 minutes Improving productivity in semi-automatic operations isn’t simply about welding faster and working harder. Instead, there are ways to create consistency in the process and support quality so that companies can avoid downtime that adversely affects throughput. When training new welders, it’s important to provide a solid foundation of knowledge to […]

- At a Glance: Cobots and the TOUGH GUN® CA3 MIG GunEstimated reading time: 4 minutes Companies today continue to face a shortage of qualified welders, but the demand for product has stayed the same — or in many cases, increased. Turning to new solutions to keep up with production can help keep the welding operation running smoothly and quickly. Tregaskiss designed its TOUGH GUN CA3 […]

- 5 Tips for Improving Weld QualityEstimated reading time: 7 minutes Establishing consistent levels of weld quality is important for attaining production goals and a better bottom line in semi-automatic welding operations. However, there are many factors that can negatively impact those efforts, including a lack of skilled labor, inadequate or aging equipment or using the wrong welding consumables. Supervisors and […]

- Is a Water-Cooled Robotic Welding Gun Necessary?Robotic welding operations can be tough on equipment. The heat from the welding arc, along with reflective heat from the base material and resistive heat from the electrical components, can wear on consumables and the robotic welding gun. In some cases, implementing a water-cooled robotic MIG gun is the answer, but many times an air-cooled […]

- From Consumables to Communication: Reducing Human Error in WeldingEstimated reading time: 4 minutes Human error can take its toll on welding operations, leading to downtime and lost productivity, poor quality and increased costs. It can result from a variety of factors. An operator may know how to manage a process, but periodically misses a step or forgets to complete a task. Or an […]

- Choosing Between Fixed Automatic, Cobot and Robotic WeldingEstimated reading time: 5 minutes Fixed welding automation is well suited to high-volume operations with a low variety of parts, such as structural beams or railcars requiring long, continuous welds or pipe that requires circular welds. No doubt manual, or semi-automatic, welding has its place across the industries — general fabrication and manufacturing, shipbuilding and […]

- MIG Welding BasicsEstimated reading time: 3 minutes When it comes to MIG welding, it’s important for new welders to start with the basics to set a solid foundation for success. The process is generally forgiving, making it simpler to learn than TIG welding, for example. It can weld most metals and, as a continuously fed process, offers […]

- MIG Welding Glossary: Terms To KnowEstimated reading time: 3 minutes Welders use MIG welding in many industries — fabrication, manufacturing, shipbuilding and rail to name a few. While it is a common process, it requires attention to detail, and it is helpful to know some key terms associated with it. As with any process, the better the understanding, the better […]

- MIG Welding Techniques: What To KnowEstimated reading time: 2 minutes Understanding some proper techniques for MIG welding can help welders gain good weld quality and avoid the frustration and cost of rework. Everything from proper positioning of the MIG welding gun to travel angle and travel speed can make an impact. Understanding some proper techniques for MIG welding can help […]

- Solving Common Causes of Welding PorosityEstimated reading time: 7 minutes Porosity, cavity-type discontinuities formed by gas entrapment during solidification, is a common but cumbersome defect in MIG welding and one with several causes. It can appear in semi-automatic or robotic applications and requires removal and rework in both cases — leading to downtime and increased costs. The major cause of […]

- Employee Retention: Best Practices for Keeping Welders EngagedEstimated reading time: 4 minutes The welding industry, like many others, is challenged by a labor shortage — and one that is growing. By 2023, the American Welding Society (AWS) anticipates the welder shortage to reach approximately 375,000, as an increasing number of experienced welders reach retirement age and leave the field.[1] With those statistics […]

- Pulsed Welding and Through-Arm Robots: What to Know

Estimated reading time: 6 minutes After early adoption by the automotive industry, the combination of pulsed gas metal arc welding (GMAW) and through-arm robots has become a more common part of automated welding operations in general manufacturing and fabrication. In fact, through-arm robots have largely replaced conventional ones in the last decade as more robot […]

Estimated reading time: 6 minutes After early adoption by the automotive industry, the combination of pulsed gas metal arc welding (GMAW) and through-arm robots has become a more common part of automated welding operations in general manufacturing and fabrication. In fact, through-arm robots have largely replaced conventional ones in the last decade as more robot […] - The Value of Welding Consumables TrialsIn both semi-automatic and automated welding cells, the upfront cost of welding consumables is low compared to the overall expense for equipment, materials and labor. Yet when companies accrue downtime for excessive welding contact tip changeover or troubleshooting poor wire feeding associated with liner issues, costs can quickly compound. Welding consumables trials can bring benefits […]

- Understanding the Impact of Time Sinks in Robotic WeldingEstimated reading time: 7 minutes No robotic welding cell operates at 100% capacity. Parts handling, fixturing, periodic rework and even employee breaks all affect a robot’s ability to be completely efficient. However, there are common time sinks that can further hinder productivity — and they can easily lead to increased costs and lower quality. Time […]

- How to Reduce Welding Gun Wear and Extend Gun LifeEstimated reading time: 5 minutes Knowing the common causes of MIG gun wear — and how to eliminate them — is a good step toward minimizing downtime and costs for addressing issues. Like any equipment in a welding operation, MIG guns are subject to routine wear and tear. The environment and the heat from the […]

- 8 Manufacturing Cost-Reduction Strategies for Welding OperationsCost overruns in a manufacturing welding operation can come from many places. Whether it’s a semi-automatic or robotic weld cell, some common culprits of unnecessary costs are unplanned downtime and lost labor, consumable waste, repairs and rework, and lack of operator training. Many of these factors are tied together and influence each other. A lack […]

- Cobots and Cobot MIG Guns: What To Know for Manufacturing Welding OperationsTraditional robotic welding systems can deliver many benefits, but they aren’t always the right solution for every manufacturer. In applications where implementing a robotic weld cell isn’t the answer, some companies are turning to collaborative robots, or cobots. While not new to the industry, cobots are currently a fast-growing and still-developing technology. They can help […]

- Creating a Smooth Wire Feeding Path for MIG WeldingIn MIG welding applications, having a smooth wire feeding path is critical. The welding wire must be able to feed easily from the spool on the feeder through the power pin, liner and gun and up to the contact tip to establish the arc. This allows the welding operator to maintain consistent levels of productivity […]

- 5 Tips for Robotic Welding Process and Project PlanningRobotic welding projects can arise in a number of ways — from a smaller shop expanding its capabilities to a large original equipment manufacturer (OEM) awarding new business or even a new company establishing itself within the competitive landscape. It’s critical to implement a well-thought-out and thoroughly researched plan to ensure a successful robotic welding […]

- Ways Welding Reamers Support Quality, Productivity and Safety

A successful robotic welding operation depends on the ability to maintain high levels of quality and productivity, while also keeping costs low. Unplanned downtime associated with consumable or equipment problems jeopardizes these goals. It can also increase the labor needed for troubleshooting and resolving issues. But above all else, the weld cell needs to be […]

A successful robotic welding operation depends on the ability to maintain high levels of quality and productivity, while also keeping costs low. Unplanned downtime associated with consumable or equipment problems jeopardizes these goals. It can also increase the labor needed for troubleshooting and resolving issues. But above all else, the weld cell needs to be […] - AccuLock Consumables Save Time and Money in MIG Consumable ChangeoverEstimated reading time: 5 minutes They may seem like small pieces of a welding operation but when consumables aren’t properly installed or maintained, big problems can result — from poor wire feeding to weld quality issues. Related troubleshooting and rework cause costly downtime and lost productivity. Consumable changeover can also be a time-consuming part of […]

- Improve Productivity by Preventing 5 Common MIG Welding Problems

Downtime and rework can be costly for manufacturing operations. The last thing any production team wants to do is the same work twice. If you add to that any time spent troubleshooting issues in the weld cell — the lost production time can start to accumulate quickly. There are several steps operations can take to reduce […]

Downtime and rework can be costly for manufacturing operations. The last thing any production team wants to do is the same work twice. If you add to that any time spent troubleshooting issues in the weld cell — the lost production time can start to accumulate quickly. There are several steps operations can take to reduce […] - Implementing a Robotic Welding System: 5 Common Questions Answered

Estimated reading time: 7 minutes Many manufacturing operations want to improve productivity and weld quality. Robotic welding can often help achieve these goals. But success with a welding robot doesn’t happen by chance. It takes a lot of upfront planning to help minimize the time and money you need later to make improvements or fix […]

Estimated reading time: 7 minutes Many manufacturing operations want to improve productivity and weld quality. Robotic welding can often help achieve these goals. But success with a welding robot doesn’t happen by chance. It takes a lot of upfront planning to help minimize the time and money you need later to make improvements or fix […] - Manufacturer Cuts $45,000 of Costs With New MIG Welding Guns and Consumables

General Kinematics — a premier manufacturer of vibrating equipment for processing bulk materials — has been providing consistent, on-time and innovative solutions to its customers for more than 60 years. The company prides itself on offering rugged, cutting-edge equipment to manage difficult-to-process materials across the mining, resource recovery, bulk processing and foundry industries. Ensuring that the […]

General Kinematics — a premier manufacturer of vibrating equipment for processing bulk materials — has been providing consistent, on-time and innovative solutions to its customers for more than 60 years. The company prides itself on offering rugged, cutting-edge equipment to manage difficult-to-process materials across the mining, resource recovery, bulk processing and foundry industries. Ensuring that the […] - How to Prevent 5 Common Welding Gun Failures

Having the right equipment in the welding operation is important — and making sure it works when it’s needed is even more so. Welding gun failures cause lost time and money, not to mention frustration. Like with many other aspects of the welding operation, the most important way to prevent this problem is education. Understanding […]

Having the right equipment in the welding operation is important — and making sure it works when it’s needed is even more so. Welding gun failures cause lost time and money, not to mention frustration. Like with many other aspects of the welding operation, the most important way to prevent this problem is education. Understanding […] - From Semi-Automatic to Automatic: Tips for Selecting a Welding Gun

Choosing the right equipment for a welding operation is critical to achieving high weld quality and productivity while also eliminating costly downtime. And that includes welding guns. In many cases, companies may have a mix of welding processes and guns. For example, in heavy equipment and general manufacturing, it’s common to have semi-automatic welding along […]

Choosing the right equipment for a welding operation is critical to achieving high weld quality and productivity while also eliminating costly downtime. And that includes welding guns. In many cases, companies may have a mix of welding processes and guns. For example, in heavy equipment and general manufacturing, it’s common to have semi-automatic welding along […] - The Importance of Cutting a Welding Liner Properly

Cutting a welding gun liner correctly is, first and foremost, a matter of proper training. For traditional systems, it’s critical that welding operators understand how to measure and cut the liner to the required length for the gun. A MIG gun liner that has been cut either too short or too long can lead to […]

Cutting a welding gun liner correctly is, first and foremost, a matter of proper training. For traditional systems, it’s critical that welding operators understand how to measure and cut the liner to the required length for the gun. A MIG gun liner that has been cut either too short or too long can lead to […] - Tips for Improving MIG Welding

Maintaining quality, productivity and cost savings is important in any semi-automatic MIG welding operation, but the steps companies take to achieve those goals vary. Still, there is one constant: the value of skilled welders. They are at the heart of the operation and help ensure its success. Having the right equipment and understanding how to […]

Maintaining quality, productivity and cost savings is important in any semi-automatic MIG welding operation, but the steps companies take to achieve those goals vary. Still, there is one constant: the value of skilled welders. They are at the heart of the operation and help ensure its success. Having the right equipment and understanding how to […] - Selecting Contact Tips for Robotic Welding

Contact tips are often referred to as the smallest fuse in the fuse box that is your robotic welding cell. But this small fuse can have a big impact on productivity. In terms of overall efficiency, the contact tip is key. Contact tips depend upon repeatability to be effective in the welding process. Learn more about […]

Contact tips are often referred to as the smallest fuse in the fuse box that is your robotic welding cell. But this small fuse can have a big impact on productivity. In terms of overall efficiency, the contact tip is key. Contact tips depend upon repeatability to be effective in the welding process. Learn more about […] - How Robotic Welding Supervisors Can Improve the Operation

Gaining a good return on investment (ROI) from a robotic welding system doesn’t happen by chance. It’s a matter of optimizing the robot and the robotic welding cell to operate at peak efficiency. And while this task is a team effort, it is led by the robotic welding supervisor. Even if a robotic welding system is meeting […]

Gaining a good return on investment (ROI) from a robotic welding system doesn’t happen by chance. It’s a matter of optimizing the robot and the robotic welding cell to operate at peak efficiency. And while this task is a team effort, it is led by the robotic welding supervisor. Even if a robotic welding system is meeting […] - Best Practices for Robotic Welding Supervisors

With careful planning and attention to detail, companies that invest in a robotic welding system can gain advantages, such as: It is important for welding supervisors to understand how to quickly troubleshoot issues and how to adjust the weld programs, as needed. • Increased productivity• High weld quality• Cost saving• Parts consistency The welding supervisor […]

With careful planning and attention to detail, companies that invest in a robotic welding system can gain advantages, such as: It is important for welding supervisors to understand how to quickly troubleshoot issues and how to adjust the weld programs, as needed. • Increased productivity• High weld quality• Cost saving• Parts consistency The welding supervisor […] - Understanding Fixed Automatic Welding Guns

Fixed automation welding is commonly used for welding pipes, structural beams, tanks and vessels in a shop environment prior to them being moved to the jobsite where they will be placed into service. When it comes to automating the welding process, many companies opt for robotic welding systems due to the flexibility they provide and […]

Fixed automation welding is commonly used for welding pipes, structural beams, tanks and vessels in a shop environment prior to them being moved to the jobsite where they will be placed into service. When it comes to automating the welding process, many companies opt for robotic welding systems due to the flexibility they provide and […] - Welding students in Tulsa benefit from Bernard MIG Guns and Consumables | Customer Testimonial

Tulsa Welding School’s Houston campus needs reliable equipment that can handle any process. Bernard® MIG guns and consumables are the answer. “Bernard (guns) they’re real comfortable in my hand you know. They’re not too big and bulky. They’re not too heavy. The neck ratio on that, is just, they’re awesome. I like them. The lighter […]

Tulsa Welding School’s Houston campus needs reliable equipment that can handle any process. Bernard® MIG guns and consumables are the answer. “Bernard (guns) they’re real comfortable in my hand you know. They’re not too big and bulky. They’re not too heavy. The neck ratio on that, is just, they’re awesome. I like them. The lighter […] - Blinn Instructors Choose Bernard MIG Guns and Consumables for Dependable Welding Equipment | Customer Testimonial

“Here at Blinn when we chose welding equipment first and foremost I want something solid. That’s going to be there for me for years. In our labs we have connected all our Miller 22 A wire feeders to Bernard guns. Centerfire is so user friendly that I actually bought conversion kits and changed all our […]

“Here at Blinn when we chose welding equipment first and foremost I want something solid. That’s going to be there for me for years. In our labs we have connected all our Miller 22 A wire feeders to Bernard guns. Centerfire is so user friendly that I actually bought conversion kits and changed all our […] - How to Prevent Common Causes of Poor Welding Wire Feeding

Poor wire feeding is a common problem encountered in many welding operations. Unfortunately, it can be a significant source of downtime and lost productivity — not to mention cost. Poor or erratic wire feeding can lead to premature failure of consumables, burnbacks, bird-nesting and more. To simplify troubleshooting, it’s best to look for issues in […]

Poor wire feeding is a common problem encountered in many welding operations. Unfortunately, it can be a significant source of downtime and lost productivity — not to mention cost. Poor or erratic wire feeding can lead to premature failure of consumables, burnbacks, bird-nesting and more. To simplify troubleshooting, it’s best to look for issues in […] - AccuLock R Consumables Reduce Downtime in Robotic Welding

In many cases, equipment-based solutions can be a means to gain success in the robotic welding operation. They can mitigate costly risks and eliminate issues that lead to inefficiencies. And often, these issues are related to a small but significant part of the robotic welding process — the welding consumables. The right welding consumables can […]

In many cases, equipment-based solutions can be a means to gain success in the robotic welding operation. They can mitigate costly risks and eliminate issues that lead to inefficiencies. And often, these issues are related to a small but significant part of the robotic welding process — the welding consumables. The right welding consumables can […] - Bernard Clean Air Fume Extraction MIG Welding Guns

For a cleaner, more compliant work environment, get right to the source and extract fumes at the weld with the Bernard Clean Air fume extraction gun.

For a cleaner, more compliant work environment, get right to the source and extract fumes at the weld with the Bernard Clean Air fume extraction gun. - Bernard BTB Semi-Automatic Air-Cooled MIG Welding Guns

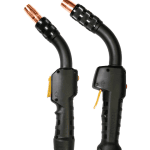

Build your ultimate MIG gun. Choose from a variety of necks, handles and trigger styles to optimize welder ergonomics and weld access. Then standardize with a single line of consumables to simplify maintenance and contain costs. You can count on Bernard BTB semi-automatic air-cooled MIG guns to deliver industrial-grade performance and reliability in the most […]

Build your ultimate MIG gun. Choose from a variety of necks, handles and trigger styles to optimize welder ergonomics and weld access. Then standardize with a single line of consumables to simplify maintenance and contain costs. You can count on Bernard BTB semi-automatic air-cooled MIG guns to deliver industrial-grade performance and reliability in the most […] - Video | Configure your Bernard Semi-Automatic MIG Gun Online

Now mobile friendly! Configure your Bernard semi-automatic MIG gun – anytime, anywhere.

Now mobile friendly! Configure your Bernard semi-automatic MIG gun – anytime, anywhere. - Bernard AccuLock S Consumables No Measuring Required

Bernard AccuLock S consumables provide error-proof liner replacement every time — no measuring required!

Bernard AccuLock S consumables provide error-proof liner replacement every time — no measuring required! - Bernard AccuLock S Consumables Dual-Locked Liner

Dual-locked in the contact tip and power pin AccuLock S liners guarantees optimized wire-feeding.

Dual-locked in the contact tip and power pin AccuLock S liners guarantees optimized wire-feeding. - TOUGH GUN TA3 Robotic Air-Cooled MIG Welding Guns

TOUGH GUN TA3 robotic air-cooled MIG guns are compatible with various through-arm style robots and provide outstanding precision and reliability. Configure to be the durable and reliable solution for best in class welding.

TOUGH GUN TA3 robotic air-cooled MIG guns are compatible with various through-arm style robots and provide outstanding precision and reliability. Configure to be the durable and reliable solution for best in class welding. - Tregaskiss Fixed Automatic MIG Guns

Engineered for hard tooling automation applications, Tregaskiss fixed automatic MIG guns are simple to maintain, durable and repeatable. They are available in air-cooled and water-cooled models.

Engineered for hard tooling automation applications, Tregaskiss fixed automatic MIG guns are simple to maintain, durable and repeatable. They are available in air-cooled and water-cooled models. - Video | Tregaskiss Fixed Automatic MIG Guns

High performance consumables with an armored neck and body plus simple internal connections equal Tregaskiss fixed automatic MIG guns. They are quick and easy to maintain for maximum up-time and throughput. Models available in air-cooled or water-cooled.

High performance consumables with an armored neck and body plus simple internal connections equal Tregaskiss fixed automatic MIG guns. They are quick and easy to maintain for maximum up-time and throughput. Models available in air-cooled or water-cooled. - Tregaskiss TOUGH GUN Reamer Robotic Nozzle Cleaning Stations

Automating spatter removal helps to extend the life of your robotic MIG welding guns and consumables. It can benefit your bottom line, production up-time and throughput. Choose between our TOUGH GUN TT4A reamer (analog model) or our new TOUGH GUN TT4E reamer (Ethernet model) for further enhanced with digital Ethernet communication for better integration.

Automating spatter removal helps to extend the life of your robotic MIG welding guns and consumables. It can benefit your bottom line, production up-time and throughput. Choose between our TOUGH GUN TT4A reamer (analog model) or our new TOUGH GUN TT4E reamer (Ethernet model) for further enhanced with digital Ethernet communication for better integration. - Video | Tregaskiss TOUGH GUN Reamer Robotic Nozzle Cleaning Stations

Tregaskiss TOUGH GUN TT4 reamer is tough on spatter and operates reliably in even the harshest welding environments. Automating spatter removal will help to extend the life of your robotic MIG guns and consumables.

Tregaskiss TOUGH GUN TT4 reamer is tough on spatter and operates reliably in even the harshest welding environments. Automating spatter removal will help to extend the life of your robotic MIG guns and consumables. - Video | Tregaskiss AccuLock R Consumables for Better Throughput

Designed for increased tip life, Tregaskiss AccuLock R consumables can reduce your replacement frequency and related planned downtime.

Designed for increased tip life, Tregaskiss AccuLock R consumables can reduce your replacement frequency and related planned downtime. - Video | Tregaskiss AccuLock HDP Contact Tips

AccuLock HDP contact tips can increase life by an additional 6-10x or more in pulse welding applications.

AccuLock HDP contact tips can increase life by an additional 6-10x or more in pulse welding applications. - Tregaskiss AccuLock R Consumables

Designed for increased tip life, Tregaskiss AccuLock R consumables can reduce your replacement frequency and related planned downtime. AccuLock HDP contact tips can increase life up to 10x in pulse welding applications.

Designed for increased tip life, Tregaskiss AccuLock R consumables can reduce your replacement frequency and related planned downtime. AccuLock HDP contact tips can increase life up to 10x in pulse welding applications. - Video | Configure your Tregaskiss Robotic MIG Gun and Reamer Online

Customize your Tregaskiss robotic MIG gun or reamer for your specific application using our new mobile-friendly online configurators!

Customize your Tregaskiss robotic MIG gun or reamer for your specific application using our new mobile-friendly online configurators! - Video | Bernard AccuLock S Consumables for the Inexperienced Welders

Choosing equipment with fewer points of failure and simplified maintenance can help support more inexperienced welders. Bernard AccuLock S consumables can reduce training and shorten your troubleshooting list so you can focus on welding productivity.

Choosing equipment with fewer points of failure and simplified maintenance can help support more inexperienced welders. Bernard AccuLock S consumables can reduce training and shorten your troubleshooting list so you can focus on welding productivity. - Video | Bernard AccuLock S Consumables for Better Productivity

Load and Lock for better productivity. Load and Lock to reduce troubleshooting, downtime and rework. Lock and Load with Bernard AccuLock S consumables.

Load and Lock for better productivity. Load and Lock to reduce troubleshooting, downtime and rework. Lock and Load with Bernard AccuLock S consumables. - How to Successfully Implement a Robotic Welding System

In today’s marketplace, companies continue to automate portions, if not all of their welding operation. The reasons are many: to address a shortage of skilled labour, to improve quality, to decrease waste and rework, and/or to increase productivity — in short, to seek benefits that provide a competitive edge. Not all companies, however, are successful […]

In today’s marketplace, companies continue to automate portions, if not all of their welding operation. The reasons are many: to address a shortage of skilled labour, to improve quality, to decrease waste and rework, and/or to increase productivity — in short, to seek benefits that provide a competitive edge. Not all companies, however, are successful […] - Improving Welding Automation Safety With Risk Assessment and Training

Download10 Tips for Robotic Welding Safety Robotic welding systems continue to gain in popularity due to their ability to increase productivity, improve quality and decrease costs in the right application. But they also offer a way to address a shortage of skilled labor for manual operations. Welding automation provide companies with a means of staying […]

Download10 Tips for Robotic Welding Safety Robotic welding systems continue to gain in popularity due to their ability to increase productivity, improve quality and decrease costs in the right application. But they also offer a way to address a shortage of skilled labor for manual operations. Welding automation provide companies with a means of staying […] - Selecting the Right MIG Welding Consumables

MIG welding gun configurators, like the Bernard® BTB semi-automatic air-cooled MIG gun configurator, allow you to choose specific styles or types of consumables to match the demands (amperages and waveforms) of your application. Selecting contact tips Know the wire size and type when choosing the size and style of contact tip. Contact tips with coarse […]

MIG welding gun configurators, like the Bernard® BTB semi-automatic air-cooled MIG gun configurator, allow you to choose specific styles or types of consumables to match the demands (amperages and waveforms) of your application. Selecting contact tips Know the wire size and type when choosing the size and style of contact tip. Contact tips with coarse […] - How to Choose MIG Welding Gun Parts

In addition to the amperage of MIG welding gun you choose, the MIG gun parts — cable, neck and handle — affect how comfortably and efficiently you can weld. Configure your gun accordingly. Choosing the cable Cable lengths can vary greatly — from 10 feet to 25 feet or longer. Use the shortest cable possible […]

In addition to the amperage of MIG welding gun you choose, the MIG gun parts — cable, neck and handle — affect how comfortably and efficiently you can weld. Configure your gun accordingly. Choosing the cable Cable lengths can vary greatly — from 10 feet to 25 feet or longer. Use the shortest cable possible […] - Configuring a MIG Welding Gun for Your Application

Have you struggled to gain proper joint access when welding? Or found yourself fatigued at the end of the day because of repeatedly welding in awkward positions? Configuring a MIG welding gun can help. Why configure? A MIG welding gun configured for the exact application can maximize efficiency and productivity. When you are more comfortable, […]

Have you struggled to gain proper joint access when welding? Or found yourself fatigued at the end of the day because of repeatedly welding in awkward positions? Configuring a MIG welding gun can help. Why configure? A MIG welding gun configured for the exact application can maximize efficiency and productivity. When you are more comfortable, […] - Common Problems With MIG Welding Consumables and How to Fix Them

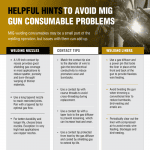

Download Helpful Hints to Avoid MIG Gun Consumable Problems MIG welding consumables are a critical but often overlooked part of the welding operation. Unfortunately, without a clear understanding of the problems that can arise with consumables — and the best way to fix them — companies stand to lose productivity, jeopardize quality and increase costs. […]

Download Helpful Hints to Avoid MIG Gun Consumable Problems MIG welding consumables are a critical but often overlooked part of the welding operation. Unfortunately, without a clear understanding of the problems that can arise with consumables — and the best way to fix them — companies stand to lose productivity, jeopardize quality and increase costs. […] - Optimizing Shielding Gas Performance in MIG Welding

Using the wrong shielding gas for MIG welding applications — or having improper gas flow — can significantly impact weld quality, costs and productivity. Shielding gas protects the molten weld pool from outside contamination, so it’s critical to choose the right gas for the job. Learn more about which gases and gas mixes are best suited for […]

Using the wrong shielding gas for MIG welding applications — or having improper gas flow — can significantly impact weld quality, costs and productivity. Shielding gas protects the molten weld pool from outside contamination, so it’s critical to choose the right gas for the job. Learn more about which gases and gas mixes are best suited for […] - 5 Misconceptions About Robotic Welding Guns and Consumables

Robotic MIG welding guns and consumables are an important part of the welding operation yet are frequently overlooked when investing in robotic welding systems. Companies may often choose the least expensive option when, in reality, purchasing quality robotic MIG guns and consumables can lead to significant cost savings in the long run. There are many […]

Robotic MIG welding guns and consumables are an important part of the welding operation yet are frequently overlooked when investing in robotic welding systems. Companies may often choose the least expensive option when, in reality, purchasing quality robotic MIG guns and consumables can lead to significant cost savings in the long run. There are many […] - MIG Welding Basics: Techniques and Tips for Success

It’s important for new welding operators to establish proper MIG techniques in order to achieve good weld quality and maximize productivity. Safety best practices are key, too. It’s just as important, however, for experienced welding operators to remember the fundamentals in order to avoid picking up habits that could negatively impact welding performance. From employing […]

It’s important for new welding operators to establish proper MIG techniques in order to achieve good weld quality and maximize productivity. Safety best practices are key, too. It’s just as important, however, for experienced welding operators to remember the fundamentals in order to avoid picking up habits that could negatively impact welding performance. From employing […] - Implementing Robotic Welding: What to Know to Be Successful

The potential advantages of robotic welding are well known — increased productivity, improved quality and greater cost savings compared to semi-automatic welding. But the question is: How do companies best implement this technology to gain these benefits? And how can they ensure a quick return on the investment (ROI)? Simply stated, planning. More preparation upfront […]

The potential advantages of robotic welding are well known — increased productivity, improved quality and greater cost savings compared to semi-automatic welding. But the question is: How do companies best implement this technology to gain these benefits? And how can they ensure a quick return on the investment (ROI)? Simply stated, planning. More preparation upfront […] - Preventive Maintenance for Reamers, Accessories and Other Peripherals

From reamers or nozzle cleaning stations to wire cutters and anti-spatter sprayers, welding peripherals and accessories can contribute significantly to the success of a robotic welding operation. In addition to improving weld quality, they can also help companies maintain high levels of productivity. A reamer requires the most attention, as this peripheral operates regularly, performing […]

From reamers or nozzle cleaning stations to wire cutters and anti-spatter sprayers, welding peripherals and accessories can contribute significantly to the success of a robotic welding operation. In addition to improving weld quality, they can also help companies maintain high levels of productivity. A reamer requires the most attention, as this peripheral operates regularly, performing […] - MIG Welding Consumables Reduce Wire Feeding Issues and Downtime

When MIG welding consumables aren’t properly installed or maintained, it can result in wire- feeding issues and weld quality problems. Troubleshooting and correcting these challenges can cost hundreds of dollars — and hours per day — in a manufacturing operation. Consumables that simplify the installation process and help eliminate errors reduce downtime for changeover and […]

When MIG welding consumables aren’t properly installed or maintained, it can result in wire- feeding issues and weld quality problems. Troubleshooting and correcting these challenges can cost hundreds of dollars — and hours per day — in a manufacturing operation. Consumables that simplify the installation process and help eliminate errors reduce downtime for changeover and […]

Articles by Category