DISCONTINUED PRODUCT — BA1 COBOT MIG GUN

Effective January 1, 2025, all Tregaskiss® BA1 cobot air-cooled MIG guns will be discontinued and replaced with TOUGH GUN® CA3 robotic air-cooled MIG guns.

| Affected Part Numbers | Direct Replacements |

| All MIG gun part numbers beginning with BA12 | Replace digits “BA12” with “RA12” (the rest of the part number remains the same) |

| All replaceable unicable part numbers beginning with BA1U | Replace digits “BA1U” with “CA3U” (the rest of the part number remains the same) |

| All replaceable unicable part numbers beginning with EBA1U | Replace digits “EBA1U” with “ECA3U” (the rest of the part number remains the same) |

The change supports our commitment to maximize efficiencies and focus on delivering our best quality solutions to our customers.

Please contact your ITW sales representative with questions.

PRODUCT UPDATE — CHANGE TO THE CABLE USED ON TOUGH GUN® CA3 MIG GUNS

PRODUCT UPDATE — CHANGE TO THE CABLE USED ON TOUGH GUN® CA3 MIG GUNS

Effective January 1, 2025, as part of our ongoing commitment to focus on opportunities to innovate our product portfolio and continue delivering sustainable value to our customers, we will be making a change to the unicable used on our TOUGH GUN® CA3 robotic air-cooled MIG guns.

The new unicable provides better flexibility in cobot and conventional over-the-arm robotic welding applications.

It is important to note the amperage rating of the TOUGH GUN® CA3 MIG gun will change from 385-amp to 350-amp with mixed gases at 100% duty cycle (ratings are based on tests that comply with IEC 60974-7 standards).

There will be no change to configured TOUGH GUN® CA3 MIG gun part numbers or its replacement or service parts.

If you have any questions about this initiative, please contact your ITW sales representative.

NEW PRODUCT: SHROUDS FOR THE TOUGH GUN® TT4 REAMER AND WIRE CUTTER

NEW PRODUCT: SHROUDS FOR THE TOUGH GUN® TT4 REAMER AND WIRE CUTTER

We are pleased to announce the launch of our new reamer shroud and wire cutter shroud. These new shrouds are intended to encourage safe practices when the TOUGH GUN® TT4 reamers are used in cobot welding applications where the operator could be near the reamer during operation.

Moving forward, all TOUGH GUN® TT4A and TT4E reamers configured specifically for use in cobot welding applications will come factory-equipped with a reamer shroud, and if the reamer is configured with the wire cutter option, the wire cutter shroud will also be factory installed.

The wire cutter can be purchased with or without the wire cutter shroud, and the reamer and the wire cutter shrouds are both available for purchase separately for customers who would like to retrofit their existing equipment, but it is important to note that if retrofitting a reamer and/or a wire cutter manufactured before March 2024, additional components will be required.

Please contact our technical support team or your local ITW representative for additional assistance if trying to retrofit older models.

TT4-SHR

Reamer shroud only, for

TOUGH GUN® TT4 reamer

WC-400C

Wire cutter equipped

with wire cutter shroud

WC-400-SHR

Wire cutter shroud only,

for wire cutter

If you have further questions or would like more information, please contact your local ITW representative.

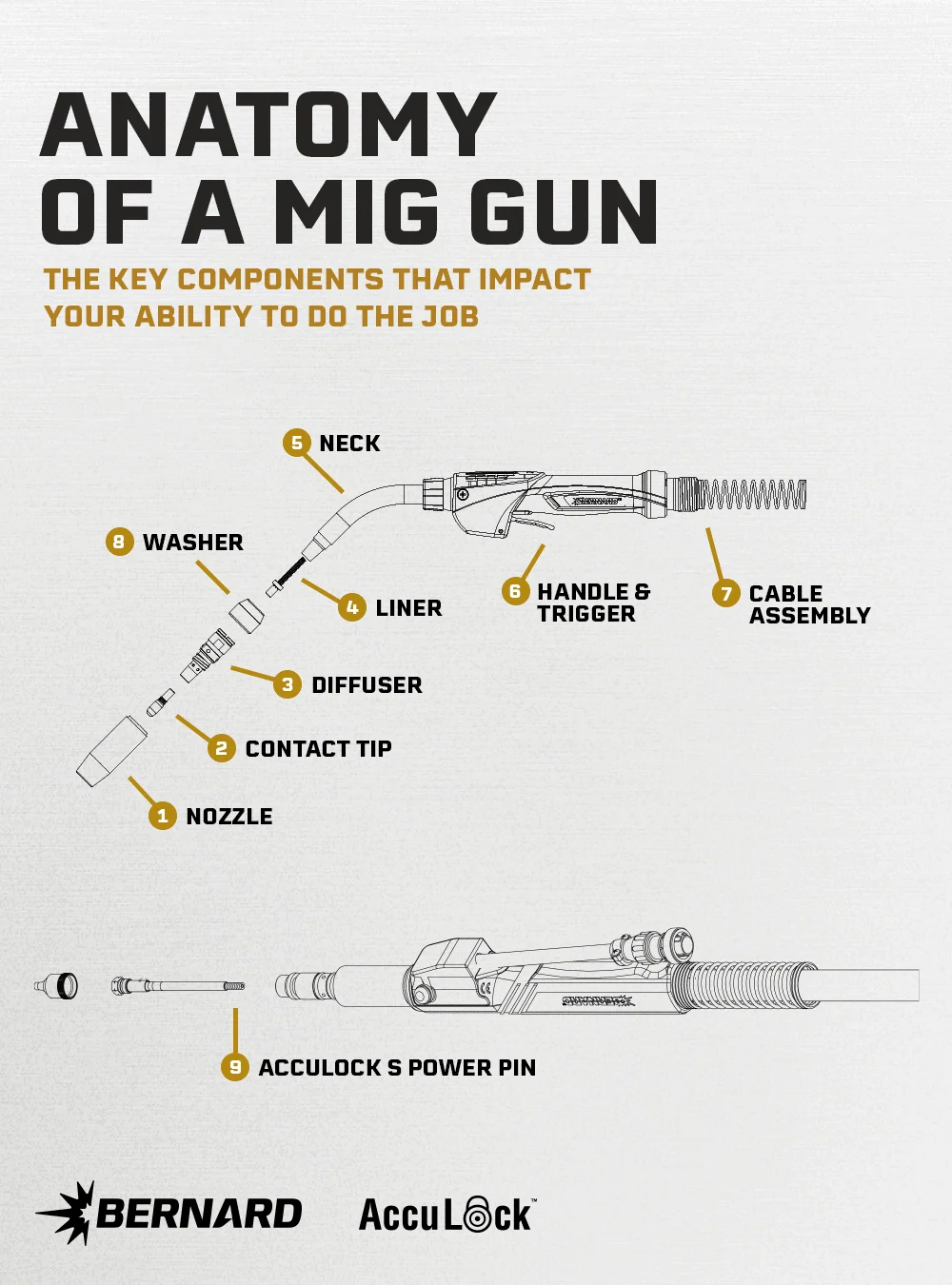

Key MIG Gun Components for Job Performance

Key MIG Gun Components for Job Performance

MIG welding is a common welding process especially useful for beginner and DIY welders due to its easy-to-learn nature, shorter lead times and lower production costs. The versatility of MIG welding allows users to work on a wide range of materials with less stopping and restarting. The process features a continuous consumable wire electrode being fed through a welding gun and into a weld pool. The gun also feeds a shielding gas alongside the wire to protect the weld pool from contaminants.

While there are different types of MIG guns that have unique parts (e.g., water-cooled, air-cooled, fume extraction), all MIG guns have some parts in common. Understanding the components of a MIG gun and the process by which it works will help you make decisions on the consumables and gun type you select for your job. Here’s what you need to know.

CONSUMABLES

1. Nozzle

- The nozzle directs the shielding gas to cover the weld puddle.

- By shielding the weld puddle, the nozzle helps to prevent spatter on the weld surface while simultaneously protecting internal components of the gun from heat and spatter.

2. Contact Tip

- The contact tip guides the wire and transfers the current from the neck through the filler metal and to the work surface. Consistent wire feeding ensures a stable arc and high weld quality.

3. Diffuser

- The diffuser conducts electricity to the contact tip while dispersing gas evenly across the weld pool.

- Ensuring even distribution of shielding gas ensures consistent coverage of the weld pool, preventing contamination and defects like porosity and oxidation.

4. Liner

- The liner is crucial to MIG welding because it guides the wire electrode from the wire feeder through the cable to the contact tip.

- A worn or low-quality liner can cause friction, leading to inconsistent feeding and arc instability and, ultimately, poor weld quality.

- There are several materials of liners for consideration, each with advantages in different applications.

ESSENTIAL GUN COMPONENTS

5. Neck

- The neck is the front-end extension of a MIG welding torch and houses vital components like the contact tip, gas nozzle and wire feeder inlet.

- It directs the welding arc and shielding gas precisely onto the weld joint, improving weld quality and consistency.

- Selecting the right neck (i.e., long versus short) is important because it impacts a welder’s posture, visibility and heat control.

6. Handle and Trigger

- The handle and trigger impacts how long an operator can weld without experiencing fatigue.

- Handles with an ergonomic design and a natural feeling grip will improve operator comfort and welding duration.

- When selecting a trigger, it needs to be responsive to the touch and best suited for the job (e.g., multi-schedule, locking).

7. Cable Assembly

- In MIG welding, the cable assembly delivers power, gas, filler metal and control signals to the welding gun.

- Without the successful transmission of each of these elements, the weld will not function as intended.

- Compression fittings are an integral aspect of the assembly because they provide a reliable connection, better energy transfer and less resistance.

OTHER COMPONENTS

8. Insulator

- Plays a critical role in electrical isolation and heat management.

- Made of a non-conductive material to help electrically isolate the metal components of the welding gun (e.g., the trigger mechanism) from the electrical circuit carrying the welding current.

- Acts as a thermal barrier between nozzle and trigger mechanism, preventing overheating and malfunctions.

9. Power Pin

- Power pins provide a direct connection for wire, weld power and gas flow between the welding machine and/or wire feeder and the MIG gun. An accurate gun-to-machine connection is critical to ensure that the filler wire, gas and weld power are passed efficiently to the gun.

New Product: Chrome Zirconium AccuLock™ Contact Tips 0.052” and 1/16” – Now Available

New Product: Chrome Zirconium AccuLock™ Contact Tips 0.052” and 1/16” – Now Available

| T-A052ZH | 0.052″ (1.3 mm); qty. 10 |

| T-A052ZH-100 | 0.052″ (1.3 mm); qty. 100 |

| T-A062ZH | 1/16″ (1.6 mm); qty. 10 |

| T-A062ZH-100 | 1/16″ (1.6 mm); qty. 100 |

Please contact the Bernard and Tregaskiss Customer Service team by phone at 1.866.MIGWELD (644.9353) or email at cs@itwmig.com with any questions.

A Fresh Look for Bernard® and Tregaskiss®

A Fresh Look for Bernard® and Tregaskiss®

We’re thrilled to announce that Bernard® and Tregaskiss® have undergone an exciting brand refresh. As of today, you will notice our updated logos and visual branding on our website, social media channels, and promotional items. This change marks a significant step forward in our journey to enhance our brands’ presence and commitment to excellence in the welding industry.

What’s New?

- Updated Logos and Brand Colors: Our new logos reflect a modern and dynamic identity for both

Bernard and Tregaskiss, while maintaining the core values and heritage of our brands. - Website Change: Our website has transitioned to www.bernardtregaskiss.com. For your

convenience, tregaskiss.com will continue to redirect to the new site. - Marketing Collateral and Promotional Items: New promo items are now available on

millerweldsstore.com and we’ve begun to provide new marketing collateral to our sales team. - Enhanced Product Packaging: Updated product packaging featuring our new branding will be

rolled out gradually as existing stock is replenished.

What’s Staying the Same?

- Unchanged Product Designs and Features: Our commitment to delivering high-quality, reliable

MIG welding solutions remains steadfast. - Product Quality and Performance: You can continue to rely on the superior performance and

durability of Bernard and Tregaskiss products. - Heritage and Expertise: Bernard’s leadership in semi-automatic MIG guns and Tregaskiss’

excellence in robotic MIG guns continue to be the foundation of our brands.

Why the Change?

In a competitive market, it’s essential to evolve and stay ahead. Our refreshed visual identity reflects our

dedication to innovation and leadership in the welding industry. By creating a more cohesive and modern brand image, we are reinforcing Bernard’s reputation as a leader in semi-automatic MIG gun solutions and Tregaskiss’ prominence in robotic MIG guns.

Impact on Products and Marketing Materials:

- Gradual Transition: Print marketing materials and product logos will be updated gradually as

existing stock is replenished. - Continued ‘Tough Gun’ Messaging: We will maintain our strong brand messaging, emphasizing the

durability and toughness of our products. - Updated Promotional Items: New promotional are now available on millerweldsstore.com.

We’re confident that these updates will strengthen our brands and provide you with an even better

experience. If you have any questions or need further information, please do not hesitate to contact us.

PRODUCT IMPROVEMENT – Change to Profile of TOUGH GUN® TA3 MIG Gun Connector Housings

PRODUCT IMPROVEMENT – Change to Profile of TOUGH GUN® TA3 MIG Gun Connector Housings

As part of our ongoing commitment to continuous improvement, we are making a change to the

TOUGH GUN® TA3 gun connector housing to accommodate an additional setscrew (see ‘Setscrew 2’

in Figure 2) which is designed to improve TCP repeatability when using long/extended length necks by providing additional support to help secure the neck firmly in place.

In order to make this change, extra thread engagement was required for the front setscrew which increased the profile of the front housing by 0.157” at the largest section (see Figure 3). And rather than the M6 x 1.0 setscrew currently used in our existing design, the new design uses two (2) M10 x 1.25 setscrews which have been tested and consistently achieved 340 in.-lbs. without causing any thread failures.

It is important to note that, like in our existing design, ‘Setscrew 1’ (see Figure 2) is responsible for the electrical (and mechanical) connection and must be installed and tightened properly, whereas ‘Setscrew 2’ is intended solely to achieve additional mechanical support. The sticker on the new gun connector housings has been revised to indicate a Step 1 / Step 2 approach (see Figure 4) to reflect this order of importance.

This incremental improvement will be rolled out as a running change as we work through current inventory, with full implementation targeted to be complete by the end of 2024.

If you have further questions or would like more information, please contact your local ITW representative.

PRODUCT UPDATE — Configurator Simplification: S-GUN™ Semi-Automatic MIG Gun Changes

PRODUCT UPDATE — Configurator Simplification: S-GUN™

Semi-Automatic MIG Gun Changes

Effective August 2024, we will simplify the configurable options of our S-Gun™ Semi-Automatic Air-Cooled MIG guns. The simplification plan includes the following:

- Cable options: Only available for 300 and 400 amps in lengths of 15 ft., 20 ft. and 25 ft.

- Handle options: Configurable with either T-Series handle (standard, locking triggers) or O-Series (standard trigger).

- Consumables: Configurable exclusively with AccuLock™ S; however, will remain compatible with entire consumable line-up to accommodate user preference.

- Power Pins: Offered with Miller®, Tweco® 4 (with Miller® lead), Euro or Lincoln® power pins.

The S-Gun™ options will be removed from the BTB Semi-Automatic Air-Cooled MIG guns online configurator. We will create a dedicated product page for S-Guns™ on our website, which will also include a separate spec sheet.

In November, we will introduce an online configurator for S-Guns™.

The options removed from the configurator will remain available for purchase until the end of 2024. After this period, these options will be re-evaluated for potential discontinuation.

These changes aim to provide a more efficient and user-friendly experience for customers.

If you have any questions or would like more information, please contact your local ITW representative.

S-Gun™ Semi-Automatic MIG Gun Timeline of Changes

Discontinued Part: Liner for 3/64”-1/16” Aluminum wire, 1910038

Discontinued Part: Liner for 3/64”-1/16” Aluminum wire, 1910038

Due to low demand, as of June 12th, 2024, part number 1910038 has been discontinued. This item can be directly replaced with part number 415-116-23.

Please contact the Bernard and Tregaskiss Customer Service team by phone at 1.866.MIGWELD (644.9353) or email at cs@itwmig.com with any questions.

Discontinued Part: Spool & Push-Pull Gun Conversion Kit SGA-4 (Fronius®)

Discontinued Part: Spool & Push-Pull Gun Conversion Kit SGA-4 (Fronius®)

Due to low demand, as of June 3rd, 2024, part number SGA-4 has been discontinued. There is no direct replacement for this part.

Please contact the Bernard and Tregaskiss Customer Service team by phone at 1.866.MIGWELD (644.9353) or email at cs@itwmig.com for any questions.

Product Update: Jump Liner No Longer Included with BTB MIG Gun

Product Update: Jump Liner No Longer Included with BTB MIG Gun

As of April 29th, if choosing a rotatable neck option for your BTB gun, they will no longer include a jump liner in the box.

If you still require and wish to purchase a replacement jump liner, they are provided based on wire size and the part number information can be found at the link below.

For questions or more information, please contact your local ITW sales representative.

Extending the Life of Welding Guns and Consumables

Extending the Life of Welding Guns and Consumables

Mastering preventive maintenance, timely consumable replacements, and proper liner trimming are key to prolonging the lifetime of MIG welding equipment. Discover proactive measures to follow for enhancing durability and performance while decreasing downtime, boosting productivity, and cutting operating costs by reading our full article in the March 2024 issue of MetalForming Magazine.

5 Factors to Consider When Choosing a MIG Welding Gun

5 Factors to Consider When Choosing a MIG Welding Gun

MIG welding is considered one of the easiest welding processes to learn and is useful for a variety of applications and industries. To maximize the benefits this versatile process offers, it is imperative to select the right MIG gun for the job. Choosing the right MIG gun directly affects efficiency, quality and safety — a trifecta every operator is trying to master to create a more comfortable and effective environment. There are five key factors when choosing the right MIG gun for your needs.

Click here to read the full article featured in the March 2024 issue of Fabricating and Metalworking Magazine.

DISCONTINUED PRODUCT – Quik Tip Contact Tip Part Number T2023 and T2030, Eliptical Contact Tip Part Number 4381A

Due to low demand, as of April 5, 2024, the part numbers in the table below have been discontinued.

| Part Number | Description | Replacement |

| T2023 | Contact tip, Quik Tip series 2, tapered, 5/16″ OD, .023″ (.6 mm) | Miller FasTip part number 209024 is a direct replacement. Must be ordered from Miller. |

| T2030 | Contact tip, Quik Tip series 2, tapered, 5/16″ OD, .030″ (.8 mm) | Miller FasTip part number 209025 is a direct replacement. Must be ordered from Miller. |

| 4381A | Contact tip, Elliptical, pipeline, .035″ (.9 mm) | 4623R insulator, DS-A2-C gas diffuser, TT-A035CH contact tip, and NST-A3818B nozzle |

Please contact the Bernard and Tregaskiss Customer Service team by phone at 1.866.MIGWELD (644.9353) or email at cs@itwmig.com for any questions.

PRODUCT UPDATE — Material Improvement for Clean-Air® Fume Extraction MIG Gun Replaceable Hose Cover

PRODUCT UPDATE — Material Improvement for Clean-Air® Fume Extraction MIG Gun Replaceable Hose Cover

You may have noticed a material improvement of the cable cover installed on all Bernard® Clean-Air™ fume extraction MIG guns. The new cable cover is more lightweight than the previous cover and allows greater flexibility of the hose assembly. Our replaceable cable cover hose protects from the damage that might be incurred on a hot workpiece, as well as extending the life of the hose for the Clean-Air fume MIG gun assembly.

For questions or more information, contact your local ITW sales representative.

PRODUCT UPDATE – Fume Extraction Neck Assembly Part Number Changes

PRODUCT UPDATE – Fume Extraction Neck Assembly Part Number Changes

Effective immediately, to simplify the ordering process on Bernard® Clean-Air® fume exhaust MIG guns, we have replaced the two parts needed to complete the complete the body assembly and vacuum tube assembly into one fume extraction neck assembly part number as shown in the chart below:

| Description | Fume Extraction Neck Assembly New Part Numbers | Discontinued Vacuum Tube Part Numbers and Body Assembly Part Numbers |

| 45° neck, medium — handle option T | 2390047 | 2390027 + 1040082 |

| 60° neck, medium — handle option T | 2390048 | 2390028 + 1040083 |

| 45° neck, medium — handle option N | 2390049 | 2390029 + 1040084 |

| 60° neck, medium — handle option N | 2390050 | 2390030 + 1040085 |

For questions or more information, contact your local ITW Representative

CONFIGURATOR SIMPLIFICATION: Changes to all automation gun configurators

CONFIGURATOR SIMPLIFICATION: Changes to all automation gun configurators

To continue delivering sustainable value to our customers, we regularly assess our product offering to ensure focus and opportunities to innovate our product portfolio.

Please be advised that, effective May 1, 2024, we are removing all TOUGH LOCK™ consumables and AutoLength pin options from our robotic, fixed automatic and cobot MIG gun configurators.

It is important to note the following:

- “AccuLock™ consumables” and “No consumables” will remain available options where currently available.

- TOUGH LOCK consumables are not being discontinued and can be ordered separately if required.

- No standard duty AccuLock consumable options will be available at this time. If standard duty consumables are required, be sure to configure the gun with the “No consumables” option and order the appropriate standard duty TOUGH LOCK consumables separately.

- Guns previously configured with TOUGH LOCK consumables and/or AutoLength pins will remain available for (re)order – no new TOUGH LOCK and/or AutoLength configurations will be available after May 1, 2024.

- AutoLength pins are not being discontinued and can be ordered separately if required.

Impacted configurators are listed below:

- TOUGH GUN TA3 ThruArm robotic air-cooled guns (TA1xxx)

- TOUGH GUN CA3 robotic air-cooled guns (RA1xxx)

- Tregaskiss 600 amp robotic water-cooled guns (RW16xxx)

- Tregaskiss MA1 fixed automatic air-cooled guns (MA16xxx)

- Tregaskiss MW1 fixed automatic water-cooled guns (MW1xxx)

- Tregaskiss BA1 cobot air-cooled guns (BA1xxx)

If you have further questions or would like more information, please contact your local ITW representative.

PRODUCT UPDATE — NEW ADDITION TO THE BERNARD FCAW SELF SHIELDED GUN PRODUCT OFFERING

PRODUCT UPDATE — NEW ADDITION TO THE BERNARD FCAW SELF-SHIELDED GUN PRODUCT OFFERING

We are proud to announce that effective immediately, a new 450-amp self-shielded FCAW series has been added to the Bernard self-shielded FCAW gun portfolio. The new IronPro™ self-shielded FCAW gun is ergonomically designed to provide excellent access and maneuverability in hard-to-reach weld joints and is ideal for rough use in harsh environments. The IronPro self-shielded FCAW guns also feature AccuLock™ S consumables to keep you welding in tight positions longer, with less contact tip changes and less troubleshooting.

Features and Benefits:

- Features AccuLock™ S consumables

- Choose from two neck sizes for different lengths and bend radii.

- Short handle better accommodates maneuverability for improved joint access.

- Sealed trigger keeps the trigger area slag and spatter free, reducing maintenance.

Ways to Save More Money With a Robotic Welding System

Ways to Save More Money With a Robotic Welding System

More and more welding operations are investing in robotic welding systems to gain a competitive edge. Such systems not only deliver fine-tuned programming to ensure the accuracy, speed and repeatability needed for generating high-quality welds, they also further productivity and efficiency for an operation. Along with the productivity gains and quality improvements, saving money is a key reason companies are choosing to implement them. Here are seven ways companies can increase cost savings and ROI — beyond the benefits of the robotic welding system itself.

Read the full article featured in Fabricating & Metalworking Magazine.

Introducing Clean Air E™

Introducing Clean Air E™

Bernard’s Clean Air E™ fume extraction MIG Gun helps create a cleaner and more productive welding environment by capturing up to 95% of fumes at the source, improving weld visibility, and reducing welder fatigue. Designed for durability in heavy industrial use, it minimizes rework, lowers compliance risks, and supports efforts to attract and retain top talent. Say goodbye to compromise and hello to precision, performance, and peace of mind.

It Starts At The Source™

Learn more: https://www.startsatthesource.com

Features and Benefits of the Clean Air E™

Features and Benefits of the Clean Air E™

Discover the Clean Air E™ difference.

Superior Fume Control Right at the Source With up to 95% source fume capture efficiency, the Clean Air E minimizes airborne contaminants, protects your team, and improves visibility on every weld. It helps you meet stringent compliance standards without compromise. Effortless Ergonomics for Extended Use Designed for welders, the Clean Air E features a balanced build, optimized handle design, and a ball swivel for added flexibility. This reduces strain and improves control, focusing on comfort and efficiency to help welders stay productive through long shifts. Industrial-Grade Durability, Reduced Downtime Built for heavy-duty use, the Clean Air E is engineered to last. Its rugged design, combined with long-life consumables, reduces maintenance demands and lowers total costs, keeping your team welding without interruption. Enhanced Visibility for Precise Welds Clearer sightlines mean better welds. The Clean Air E is designed to minimize arc obstructions, providing improved visibility and weld access. With a better view of the weld puddle, welders can work with greater accuracy, control, and consistency.

Want to learn more? Click here.

PRODUCT UPDATE — ACCULOCK™ S CONSUMABLES AND NEW NECK ON XS180 AND XS 260 TGX™ SERIES MIG GUNS

PRODUCT UPDATE — ACCULOCK™ S Consumables and New Neck on XS180 AND XS 260 TGX™ Series MIG Guns

We are pleased to announce that on March 1, 2024, we started offering XS180 and XS260 TGX (10’ and 15’) MIG guns with Bernard neck, silver color (part number 205-60) and AccuLock™ S consumables with Bernard® conventional liner.

DISCONTINUED PRODUCT – TGX Series MIG Gun Amperages

DISCONTINUED PRODUCT – TGX Series MIG Gun Amperages

To continue delivering sustainable value to our customers, we regularly assess our product offering to ensure focus on customer needs and opportunities to innovate our product portfolio. Accordingly, as of March 1, 2024, we have discontinued the XS300, XL300 and XL400 amp TGX air-cooled MIG guns. We are recommending our 200-amp Bernard BTB MIG guns to replace XS300, XL300 and 300-amp Bernard BTB Mig guns to replace XL400 amp TGX air-cooled MIG guns.

NOTE: We will continue to support all XS180 and XS260 TGX air-cooled MIG guns.

DISCONTINUED PRODUCT – Select Reamer Stand Heights

DISCONTINUED PRODUCT – Select Reamer Stand Heights

In effort to maximize efficiencies and continue to focus on delivering sustainable value to our customers, effective December 20, 2023, we will be discontinuing a variety of reamer stands due to low demand and sales volume.

| Part Number | Description |

|---|---|

| RST-20 | Reamer stand, 20-inch |

| RST-22 | Reamer stand, 22-inch |

| RST-23 | Reamer stand, 23-inch |

| RST-27 | Reamer stand, 27-inch |

| RST-29 | Reamer stand, 29-inch |

| RST-32 | Reamer stand, 32-inch |

| RST-35 | Reamer stand, 35-inch |

| RST-40 | Reamer stand, 40-inch |

| RST-45 | Reamer stand, 45-inch |

TOUGH GUN® reamer stands are still part of our product portfolio and will remain available, in heights between 18 and 36 inches in 6-inch increments.